Page 49 - Wood Review Dec 202 Full issue

P. 49

WOODCARVING

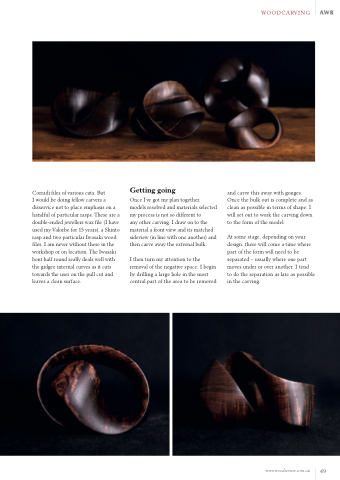

Corradi files of various cuts. But

I would be doing fellow carvers a disservice not to place emphasis on a handful of particular rasps. These are a double-ended jewellers wax file (I have used my Valorbe for 15 years), a Shinto rasp and two particular Iwasaki wood files. I am never without these in the workshop or on location. The Iwasaki bent half round really deals well with the gidgee internal curves as it cuts towards the user on the pull cut and leaves a clean surface.

Getting going

Once I’ve got my plan together, models resolved and materials selected my process is not so different to

any other carving. I draw on to the material a front view and its matched sideview (in line with one another) and then carve away the external bulk.

I then turn my attention to the removal of the negative space. I begin by drilling a large hole in the most central part of the area to be removed

and carve this away with gouges. Once the bulk out is complete and as clean as possible in terms of shape, I will set out to work the carving down to the form of the model.

At some stage, depending on your design, there will come a time where part of the form will need to be separated – usually where one part moves under or over another. I tend to do the separation as late as possible in the carving.

www.woodreview.com.au 49