Page 61 - Zero Net Energy Case Study Homes-Volume 2

P. 61

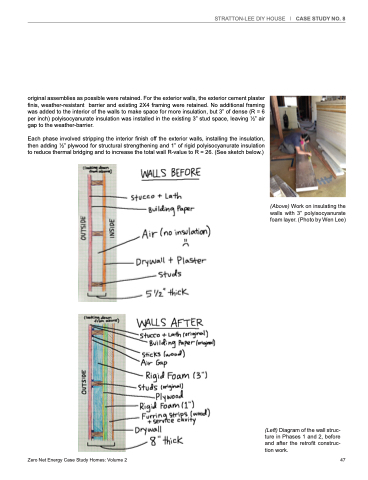

original assemblies as possible were retained. For the exterior walls, the exterior cement plaster finis, weather-resistant barrier and existing 2X4 framing were retained. No additional framing was added to the interior of the walls to make space for more insulation, but 3” of dense (R = 6 per inch) polyisocyanurate insulation was installed in the existing 3” stud space, leaving 1⁄2” air gap to the weather-barrier.

Each phase involved stripping the interior finish off the exterior walls, installing the insulation, then adding 1⁄2” plywood for structural strengthening and 1” of rigid polyisocyanurate insulation to reduce thermal bridging and to increase the total wall R-value to R = 26. (See sketch below.)

STRATTON-LEE DIY HOUSE

CASE STUDY NO. 8

(Above) Work on insulating the walls with 3” polyisocyanurate foam layer. (Photo by Wen Lee)

Zero Net Energy Case Study Homes: Volume 2

47

(Left) Diagram of the wall struc- ture in Phases 1 and 2, before and after the retrofit construc- tion work.