Page 30 - Zero Net Energy Case Study Buildings-Volume 1

P. 30

CASE STUDY NO. 1

PACKARD FOUNDATION HEADQUARTERS BUILDING

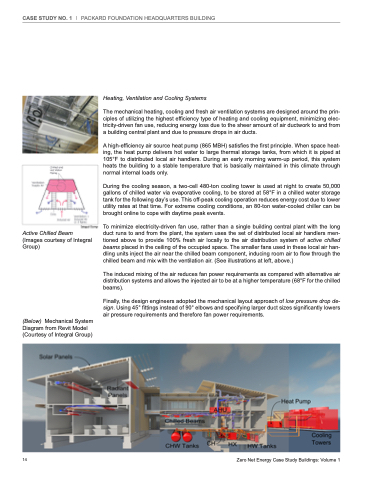

Active Chilled Beam

(Images courtesy of Integral Group)

(Below) Mechanical System Diagram from Revit Model (Courtesy of Integral Group)

Heating, Ventilation and Cooling Systems

The mechanical heating, cooling and fresh air ventilation systems are designed around the prin- ciples of utilizing the highest efficiency type of heating and cooling equipment, minimizing elec- tricity-driven fan use, reducing energy loss due to the sheer amount of air ductwork to and from a building central plant and due to pressure drops in air ducts.

A high-efficiency air source heat pump (865 MBH) satisfies the first principle. When space heat- ing, the heat pump delivers hot water to large thermal storage tanks, from which it is piped at 105°F to distributed local air handlers. During an early morning warm-up period, this system heats the building to a stable temperature that is basically maintained in this climate through normal internal loads only.

During the cooling season, a two-cell 480-ton cooling tower is used at night to create 50,000 gallons of chilled water via evaporative cooling, to be stored at 58°F in a chilled water storage tank for the following day’s use. This off-peak cooling operation reduces energy cost due to lower utility rates at that time. For extreme cooling conditions, an 80-ton water-cooled chiller can be brought online to cope with daytime peak events.

To minimize electricity-driven fan use, rather than a single building central plant with the long duct runs to and from the plant, the system uses the set of distributed local air handlers men- tioned above to provide 100% fresh air locally to the air distribution system of active chilled beams placed in the ceiling of the occupied space. The smaller fans used in these local air han- dling units inject the air near the chilled beam component, inducing room air to flow through the chilled beam and mix with the ventilation air. (See illustrations at left, above.)

The induced mixing of the air reduces fan power requirements as compared with alternative air distribution systems and allows the injected air to be at a higher temperature (68°F for the chilled beams).

Finally, the design engineers adopted the mechanical layout approach of low pressure drop de- sign. Using 45° fittings instead of 90° elbows and specifying larger duct sizes significantly lowers air pressure requirements and therefore fan power requirements.

14

Zero Net Energy Case Study Buildings: Volume 1