Page 27 - NEW Armstrong Book - 2

P. 27

S

ilicon power devices have traditionally been used to control power-electronic systems in vehicles, such as main inverter motors, pumps, HVAC compres-

By Maurizio Di Paolo Emilio

The benefits of using SiC technology in inverters include smaller circuits and lower weight, improving the solution’s weight distribution and reducing overall power consump- tion. The size and weight reductions are possible because SiC MOSFETs can be operated at a much higher switching frequency, reducing the size of many of the circuit elements needed in the inverter. SiC devices can also operate at higher voltages and currents than standard silicon power semicon- ductors, increasing power density and reducing switching losses even at high temperatures.

The use of SiC in the power inverter improves the car’s per- formance while allowing increased torque and acceleration.

Another key property is thermal conductivity, which indicates how easy it is to extract the heat generated by power losses in the semiconductor device and thereby prevent the operat- ing temperature of the device from rising dangerously. For semiconductor-based devices with low thermal conductiv- ity, such as silicon, it is more difficult to keep the operating temperature low. An operating mode known as de-

The Next Wave of Semiconductors with SiC

sors, and braking and steering systems. Recent advance- ments based on compound semiconductor devices such as silicon carbide have increased the efficiency of most auto- motive systems. Certain SiC device characteristics, such as low conduction and switching losses, zero-recovery body diode, and high operating junction temperature, make the technology very suitable for automotive applications, in which efficiency is key.

As a wide-bandgap semiconductor, SiC exhibits a larger bandgap energy than silicon (3.2 eV, about 3× higher than silicon’s 1.1 eV). Because more energy is required to excite a valence electron in the conductive band of the semiconduc- tor, higher breakdown voltages, higher efficiency, and better thermal stability at high temperatures can be achieved. The main advantage of a SiC MOSFET is the low drain-to-source on-resistance (RDS(on)), up to 300× to 400× lower than that of silicon devices at the same breakdown voltage.

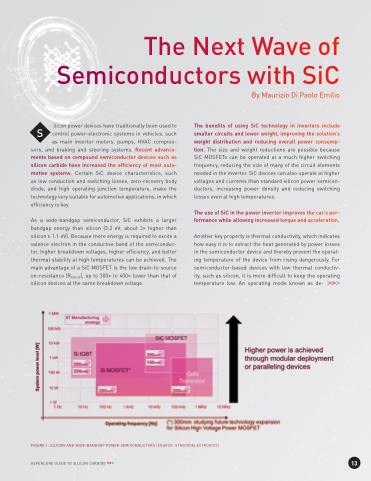

FIGURE 1: SILICON AND WIDE-BANDGAP POWER SEMICONDUCTORS (SOURCE: STMICROELECTRONICS)

ASPENCORE GUIDE TO SILICON CARBIDE

3

1

13

Technology Analysis Headline Here