Page 26 - Toyota Annual Directory 2020-2021

P. 26

Cycle Time reduction (sec) Change over reduction (sec)

263,6 sec 186 sec

Tab hoursworked)Welder80084*Prerecorded

P

P

Cup Holder

D

Glue Glue Skins

PU Align Weld RHS

Mbr 1 c/t Mbr 2 c/t older Process KaiIznietianl Yamazumi [s]

C

A

2 mbr process

40

30 A

n ation

- Reduce muda (hand,

Eliminate non value add. ReducedEnd pro - 27.7 labour hours / week reduction (-22%)

s

b

i

CA

2 mbr process

58.1

∑

/t reduction:1-1V8sid→eo71asn(-a4l0y%s)is -24.4

l

a

b

our hrs /wefeekeret)duction

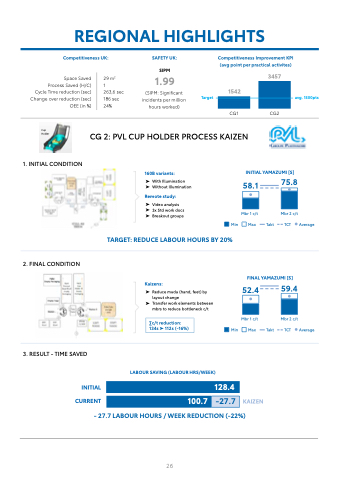

Min Max Takt TCT Target: Reduce labour hours by 20%

Average

75.8

Mbr 2 c/t

Front Glue Rear Glue

2. FINAL CONDITION

D

2) Final Condition: Mbr 1 c/t

1

58.1

Takt TCT Average 9 mbrs / 2 shift

Min Max

Takt

TCT

Average

Kaizens:

C A 3) Result - time saved

FG Stillage

s co

REGIONAL HIGHLIGHTS

REGIONAL HIGHLIGHTS

Management Control Improvements UK: Competitiveness UK: Start of Year End of Year

AGC Internal Use Only.#

Start of Year End of Year SIPM

OECEG(i2n:%P)VL CupV2Hi4suo%aldisienrg PthreoacbensosrmKalitzyen X.X

ac

k

1) Initial Condition

1. With Illumination

D

hours worked)

Welder

75.8

UTE

Mbr 1 c/t

Min Max

3) Result - time saved

- 27.7 labour hours / week reduction (-22%)

26

Maintain & improve

2) Final Condition:

Mach9 minbres /C2 Tshirfteduction

Walk Way

Safety

UK:

#

H (avg point per practicalCaGct1i:v1it6e0sB) Armrest Wrapping Pro

X

Settingthestandard RXe.XgionalCoX.mX2petitMivaneunfaectsusrin+gsSp P 1)FF/RRArmrestC3e4ll5-R7emoteStudy

(SIPStMar:t SofigYenairficaEnntd of Year

incidents per million

End

of

Line

Setting the standard RXe.Xgional CoX.mX petitMivaenu

0

Target:-

hours worked)

X.X

X.X X.X

Front Glue

Rack

XX

XX seconds

0

0

0 Significant

10 WELD/EOL ΣCT EinOLcidents per million

- 27.7 labour hours / week reduction (-22%) No. of processes required (∑c/t /TCT)

Mbr 1 c/t

Mbr 2 c/t

Machine 1501

Initial Yamazumi [s]

FINAL YAMAZUMI [S]

c

m

n

ed

Mbr 1 c/t

Welder

Walk Way

End of Line

Min

Mbr 2 c/t

➤MbBrr1eca/ktout groups

= 1.3 (SOP) → 1.02 (2021)

Mbr 2 c/t Edge Wrap Target: reduce to 1 mbr process

Remote study:

S

Max Takt 3) Result - time saved

TCT Average

Initial Yamazumi - 160B [s] M

CHUT

E

Min

60

TARGET: RE-D27U.7 laCboEur hLoAursB/ wOeekUreRducHtionO(-2U2%R) S BY 20%No. of processes required (∑c/t /TCT)

P

elements between

➤ Transfer work elements between mbrs to redmucbers to reduce bottleneck c/t Tab

Small Walk s t i l l 6r 4e . q1 ' d

bottleneck c/t

Max Ta

Mbr 2 c/t

∑

c/t

red

Min

30

20

T10CT Average

Auto c/t

Target: Reduce labou

134s → 112s (-16%)

Tab 0A

Autoc/t

Min Max

Takt TCT Average Min Max Target:reduceto1mbrprocess

0 ∑c/t reduction:118s→71s(-40%) CELL LAYOUT

59.4

Average CHUTE - Video analysis 1

LABOUR SAVING (LABOUR HRS/WEEK)

Mbr 2 c/t

CHUTE

Small table for clips

OP

- 27.7 LABOUR HOURS / WEEK REDUCTION (-22%)

Takt TCT

CAROUSEL

HOLDING TABLE

10 5

114 69

FG Stillage

AGC Internal Use Only.

#

REGIONAL HIGHLIGHTS

Management Control Improvements UK: Competitiveness UK:

Competitiveness UK: SAFETY UK:

Competitiveness Improvement KPI

Safety UK:

SIPM

1SIPM CG 1: 160B Armrest Wrapping Process Kaizen

GyingKIPOI XX RN

acefEesatv

AL HIG

LIGHTS

hours wo

ed)

Target

0 avg. 1500pts

12 78 6 C A R O U S E L 3973

- Std work docs

- Breakout groups

k

Edge Wrap

Edge W

rap

70EdgeW0 SIPM

a ec t n

P I X X

2 8 45

Rear Glue

0 Man 20

ur

/

F

h

o

ro

nt G

lue

600Videoanalysis.

v

3

10

CELL LAYOUT

- Std work docs

- Breakout groups

64.1 62.9 55.4 71.0 71.0

-

s

52.4

2 We

lding

machi

ne

HOLDING TABLE

Rack

1) Init

i

MFainxal YamazumTia- k16t0B [s] TCT Average 50 at lower volume)

17

2 8 6

3 109

CAROUSEL

734 5859

6

FG Stillage

from mbr to rob - Improve 4s

4

11

n

c

table for

clips

Edge Wrap

70

Current

CH

tatus:

Mbr 1 c/t

CMoamx pactTakt

40

cell

Min Max

mrest Assy - Inital 10 Safe

rap Edge Wrap 707 6

59.4

1 CAROUSEL

1 mb4)rNperxotcsetespss:

20 - Yokoten to 162B (26hr scope)

Mbr1c/t Mbr2c/t =1.3(ASuOtoPc/)t →1.M0b2r1(c2/t021)Mbr2c/t 10

AGC Internal Use Only.

Setting the standSarpd aceRXeS.Xgaiovenadl CoX.mX p2et9itMmivaenunfaectsusrin+g sSpacefesatvyingKPI XX m2 X.XX

Visualising the abnormality X.X Visualising the abnormality X.X X.X

X.X Man/hour XX hours P 1) FF / RR Armrest Cell - Remote Study

Maintain & improve X.X MaPinrtoainc&eimspsroSveavedX.(XH/C) X.X

Man/hour XX ho

(SIPM: Significant incidents per million

Walk Way

Front Ar

Method:-

* Two teams

urs

X.X Machine CT reduction XX seconds

Front Armrest Assy - Inital

.99

2 m

X.X

(SIPM: Significant

1 ManaMgacehmineeCTnrtedCucotionntrolXXImsecponrdos vements UK: incidentsCpoermipllioentitiveness UK: ty UK:

Walk Way

0 92 Tab0

r

Welde9r0 End of Line

1

542

9

0

susrin+g sSpacefesatyingK

50 40

CG 2: PVL Cup Holder Process Kaizen

f

0

.XX

* KaizPen Pr1oc)eFssF / RR

* Reduce end

Process by >8's

R

2) Identify MUDA

AGC Internal UseOnClyE. SS

CG1 0

C 3) Confirmation

CG2

Glue Substrate

Glue Skins PU Align PU Align Weld

* Combine P

PU Align LHS

r

ocess

m2

605 504 403

hours 302 Rear Glue (SIPM201:

LHS 9 mRbHrSs / 2 shift

4) Result - timeSusbastvraeted

C 3 ) C- 7 o8 n f i r m a t i o n

f r o m c e l l .

9 808

0

Ta

b

X

160B variants: 1) Initial Condition

Kaizens:

D

2) Final Condition:

- Reduce muda (hand,

Eliminate non value add. ReducedEnd process combined

One process removed

K:

d o f Y e a r

1. INITIAL CONDITION

Final Yamazumi [s]

∑ reduction: c/t

Combined

Walk Way

Kaizens:

increases D 2) Identif Initial

t:hou Holder - Video analysis

in

atio

n

Cup

mbrs to reduce bottleneck c/t

7

0

624

90 (Hours/week)

AL HIGHLIGHTS

- Transfer work

60 50

still req'd

100

80 702

Competitiveness UK:

Safety UK:

Compact <LOGElOim>inate or Trim Process Kaizen <LOAGO5>) Next

2 oX.mX petitMivaneunfaectsusrin+g sSpacefesatvyingKPI XX m

160B

.1

Kaizens:

2. Witho1u6t0IlBlu

1. With Illumination

f e e t ) b y l a y o u t c h a n g e

# K a i z e n s W: a l k i n g

D 2 ) I d e n t i f y M U D A 100

4 ) R e s u

Front Glue

Remote2s.tuWdyi

t Illum

t) by

layo

ut

cha

nge

W

a

lk

- 3x Std work docs

t

s

b

4

0

- Breakout groups Remote study:

∑ reduction: c/t

W

a

lk W

ay

Compact

30 20 10

Initial K70aizen FinSaml all Walk

mvainrai

CG

VL CUP HOLDER PR

KAIZ

atinonts:

CG 2: PVL Cup Holder Process Kaizen Eliminate non value add. Reduced

- Video analysis

- 3x Std work docs - Breakout groups

1) Initial Condition

Cup

H o l d e r

134s → 112s (-16%) 160B variants:

D 2) Final Condition: bottleneck c/t cell

A

60

Study proscteislls r2efqur'dther. Could

2: P

EN

P

TWaeblder 0Tab

50 40 30 20 10

- Transfer work Waiting for machine 90

- Reduce muda (hand, End process combined

elements between Walk Way 80

ing Small Walk

702 (-12%)

1. With Illumination

134s →C1G12s: (M-1o6%lle) rtech Back Do Welder

- Reduce mu

da (hand,

59.4

52.4 2. Without Illumination

feet) by layout Ccohmabningeed Walking INITIACLGYA1M:A1ZU6M0IB[S]Armrest Wrap - Transfer work Waiting fo

160B variants:

fee

etween mbrs to reduce

elemen

Walk Way

Tab

W

a

iting for machine

Welder

End of Line

Welder

End of Line

combine if TMUK TAKT

Tab

cell

0

5) Next Steps -

F i nS aI Pl YMa m a z u m i [ s ] ➤ With Illumination

1 ) I n i t i a l C o n d i t i o n

2 ) F i n a l C o n d i t i o n 3 ) R e s u l t - t i m e s a v e d

C Walk Way

Remote study:

➤ W- VitihdeoouatnIlalluysmisination

D

elements between

X.XX

CG 2: Mollertech Back Door Trim Process Ka

P

59.4

75.8

58

mbrs to reduce

izen

52.4

- Utilise spare capacity

Tab Welder

P

- Redubceomttuldean(heacnkd,c/t

1) FF / RR Armrest Cell - Remote Study

X.X X.X

Man/hour Machine CT reduction

Initial Yamazumi [s]

XX hourMs in Max XX seconds

- Video analysis

- Std work docsP - Breakout groups

feet)

C A

3) Result - time saved

90 80

Welder

Mbr 1 c/t

- 3x MStbdrw2 oc/rtk docs RTeamkt -oBtreTeCasTktoutdAgvyreo:ruapges

Remote study:

CHUTE

(SIPM: Significant in➤cideVnidtsepoearnmalilylisoisn

1

56 9 y

OP CAROUSEL

2) Final Condition

Tab

CELL LAYOUT

Machine 1501

Walk Wa

8

FG Stillage

2 mbr process

Tab

Welder

W e l d i n g m a c h i n e

Front Armrest A

HOLDING TABLE

(-45%)

12 78 3

11

6 C A R O U S E L 2 10 95 7 34

from mbr to robot

4

134s → 112s (-16%)

CHUTE Small table for clips

Walk Way

➤ho3uxrsSwtdowrkoerdk)docs FinalYamazumi[s]

End of Line

1 mbr process

- T r a n s f e r∑m o r er ew do ruk c t i o n : 1) Initial Condition c/t D

-1Im6p0rBove 4s

Kaizens:

- Utilise spare ca - Reduce muda (

7

Mould c/t increase (accepCtabGle 2: - Transfer more

Sm

Oa l l P

Mbr 1 c/t Mbr 2 c/t Glue Glue Skins PU Align PU

Initial Yamazumi - 160B [s]

Final Yamazumi - 160B [s]

Min Max Takt 64.1 62.9

TCT Average

55.4 71.0 713 .0 9

CHUTE

2) Identify MUDA

C 3) Confirmat2iomnbr process

D

Walk Way

HOLDING TABLE

Auto c/t Mbr 1 c/t Mbr 2 c/t

Au

to Average Min

Substrate LHS

e

c/

t

M

br

1c

/

t

Mbr 2

12 78 6 C A R O U S E L 114105

2 7 34

856 9

Target: Reduce labour hours by 20%

Kaizens:

Min Max

Takt

TCT

59.4

Max

No. of process

feet) by layout change Walking ➤ Redu7c5e.m8uda (hand, feet) by

52.4

100

Takt TCT Ave = 1.3 (SO

Target: redu Initial Y

58-.1Transfer work Waiting for machine

90

80

70

60

50

layout change

kt TCT Average ∑c/t reduction:

uction:

134s ➤ 112s (-16%) r hours by 20%

3. RESULT - TIME SAVED

CG 2: Mollertech Back Door Trim Proces

Final Yamazumi [s]

52.4

INITIAL CURRENT

Welder

Combined

1) Initial C

ondition

160B

KAIZEN

Remote study:

D

W e l d i n g m a c h i n e

2) Final Co

P

128.4

Kaiz - Uti - Re feet - Tra fro

- Im

∑c/t reduction:118s

100.7

CELL LA

-27.7

YOUT

Machine 1501

No. of processes required (∑c/t /TCT) = 1.3 (SOP) → 1.02 (2021) Target:reduceto1mbrprocess

1 mbr process

Initial Yamazumi - 160B [s]

Final Yamazu

N

C

y

n r

s

h

wM o

R

oe P

s

a

s

n

e l d )

m p

→ m

c

Edge Wrap

Edge Wrap

Edge Wrap

Edge Wrap

X

X

Thinsulate pads Holding dolly

HOLDING TABLE

WELDING MACHINE

MWAECLDHINGE

M/C 1501

ThHionlsduinlagtedoplalyds

HOLDING TABLE

Thinsulate pads

WELDING MACHINE

M/C 1501

ThHionlsduinlagtedoplalyds

HOLDING TABLE

MWAECLDHINGE

M/C 1501

M/C 1501