Page 21 - NIDUAE

P. 21

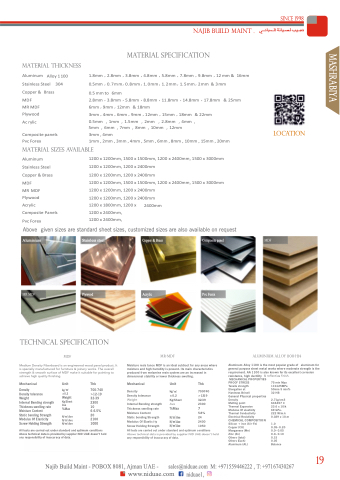

Stainless Steel Copper & Brass MDF MR MDF Plywood Ac rylic 304 Najib build maint . Since 1998 Material Thickness Aluminum Alloy 1 100 Material specification 1.8mm , 2.8mm , 3.8mm , 4.8mm , 5.8mm , 7.8mm , 9.8mm , 12mm & 16mm 0.5mm , 0.7mm, 0.8mm , 1.0mm , 1.2mm , 1.5mm , 2mm & 3mm 0.5 mm to 6mm 2.8mm , 3.8mm , 5.8mm , 8.8mm , 11.8mm , 14.8mm , 17.8mm & 25mm 6mm,9mm,12mm&18mm 3mm,4mm,6mm,9mm,12mm ,15mm ,18mm &22mm 0.5mm ,1mm ,1.5mm ,2mm ,2.8mm ,4mm , 5mm ,6mm ,7mm ,8mm ,10mm ,12mm 3mm , 4mm 1mm , 2mm , 3mm , 4mm , 5mm , 6mm , 8mm , 10mm , 15mm , 20mm Composite panels Pvc Forex location Material Sizes Available Aluminum Stainless Steel Copper & Brass MDF MR MDF Plywood Acrylic Composite Panels Pvc Forex 1200 x 1200mm, 1200 x 1200mm, 1200 x 1200mm, 1200 x 1200mm, 1200 x 1200mm, 1200 x 1200mm, 1200 x 1800mm, 1200 x 2400mm, 1200 x 2400mm, 1500 x 1200 x 1200 x 1500 x 1200 x 1200 x 1200 x 1500mm, 1200 x 2400mm, 1500 x 3000mm 2400mm 2400mm 1500mm, 1200 x 2400mm, 1500 x 3000mm 2400mm 2400mm 2400mm Above given sizes are standard sheet sizes, customized sizes are also available on request Aluminium Stainless steel Plywood Technical specification Copper & Brass Acrylic Mr-MDF Moisture resis tance MDF is an ideal subtract for any areas where moisture and high humidity is present. Its main characteristics produced from melamine resin system are an increased in dimensional stability or lower thickness swelling. Composite panel Pvc Forex MDF Unit kg/ m3 ±0.2 Weight Kg/Sheet Ave %Max 2 N/mmAve 2 N/mmAve N/ mm2 Ave Aluminium alloy 1100-h14 Aluminum Alloy 1100 is the most popular grade of aluminum for general purpose sheet metal works where moderate strength is the requirement. AA 1100 is also known for its excellent corrosion Mechanical Density Density tolerance Weight Internal Bending strength Thickness swelling rate Moisture Content Static bending Strength Modulus Of Elasticity Screw Holding Strength Thk 700-740 >12-19 32-39 2300 10 6-6.5% 20 2100 1000 Mechanical Densi ty Density tolerance Unit Thk resistance, high ductility MECHANICAL PROPERTIES PROOF STRESS Tensile strength Elongation at Hardness Brinell General Physical properties Density Melting point Thermal Expansion Modulus Of elasticity Thermal Conductivity Electrical Resistivity CHEMICAL COMPOSITION Silicon + iron (Si+Fe) Copper (CU) Manganese (Mn) Zinc (Zn) Others (total) Others (Each) Aluminum (AL) e 75 min Mpa 110-125MPa 50mm 5 min% 32 HB 2.71g/cm3 643-657 C 23.6 x 10/k 69 GPa. 222 W/m.k 0.029 z 10.m 1.0 0.05– 0.20 0.0– 0.05 0.0– 0.10 0.15 0.05 Balance 3 kg/ m ±0.2 Kg/Sheet 700-740 >12-19 32-39 2300 All tests are carried out under standard and optimum conditions Above technical data is provided by supplier NID U AE doesn’t hold any responsibility of inaccuracy of data. N/mmAve 1050 any responsibility of inaccuracy of data. Internal Bending strength Thickness swelling rate Moisture Content Static bending Strength Modulus Of Elastici ty Screw Holding Strength All tests are carried out under standard and optimum conditions %Max 7 5-8% 24 2 N/mmAve 2 N/mmAve 2400 2 Najib Build Maint - POBOX 8081, Ajman UAE - E:sales@niduae.com M: +971559446222 , T: +97167430267 www.niduae.com niduae1, niduae 19 MASHRABIYA