Page 12 - Penn State Mechanical Engineering Magazine 2020

P. 12

Response to COVID-19

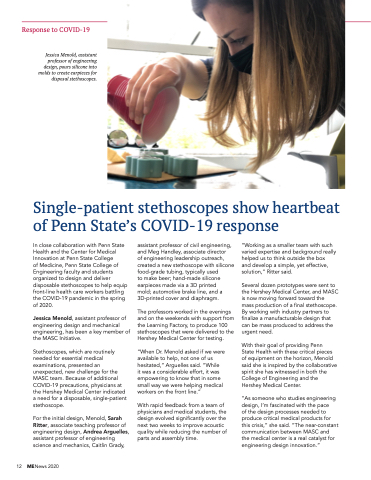

Jessica Menold, assistant professor of engineering design, pours silicone into molds to create earpieces for disposal stethoscopes.

Single-patient stethoscopes show heartbeat of Penn State’s COVID-19 response

In close collaboration with Penn State Health and the Center for Medical Innovation at Penn State College

of Medicine, Penn State College of Engineering faculty and students organized to design and deliver disposable stethoscopes to help equip front-line health care workers battling the COVID-19 pandemic in the spring of 2020.

Jessica Menold, assistant professor of engineering design and mechanical engineering, has been a key member of the MASC Initiative.

Stethoscopes, which are routinely needed for essential medical examinations, presented an unexpected, new challenge for the MASC team. Because of additional COVID-19 precautions, physicians at the Hershey Medical Center indicated a need for a disposable, single-patient stethoscope.

For the initial design, Menold, Sarah Ritter, associate teaching professor of engineering design, Andrea Arguelles, assistant professor of engineering science and mechanics, Caitlin Grady,

assistant professor of civil engineering, and Meg Handley, associate director

of engineering leadership outreach, created a new stethoscope with silicone food-grade tubing, typically used

to make beer; hand-made silicone earpieces made via a 3D printed mold; automotive brake line, and a 3D-printed cover and diaphragm.

The professors worked in the evenings and on the weekends with support from the Learning Factory, to produce 100 stethoscopes that were delivered to the Hershey Medical Center for testing.

“When Dr. Menold asked if we were available to help, not one of us hesitated,” Arguelles said. “While

it was a considerable effort, it was empowering to know that in some small way we were helping medical workers on the front line.”

With rapid feedback from a team of physicians and medical students, the design evolved significantly over the next two weeks to improve acoustic quality while reducing the number of parts and assembly time.

“Working as a smaller team with such varied expertise and background really helped us to think outside the box

and develop a simple, yet effective, solution,” Ritter said.

Several dozen prototypes were sent to the Hershey Medical Center, and MASC is now moving forward toward the

mass production of a final stethoscope. By working with industry partners to finalize a manufacturable design that can be mass produced to address the urgent need.

With their goal of providing Penn

State Health with these critical pieces of equipment on the horizon, Menold said she is inspired by the collaborative spirit she has witnessed in both the College of Engineering and the Hershey Medical Center.

“As someone who studies engineering design, I’m fascinated with the pace

of the design processes needed to produce critical medical products for this crisis,” she said. “The near-constant communication between MASC and the medical center is a real catalyst for engineering design innovation.”

12 MENews 2020