Page 27 - ConcreCem - State of the Art

P. 27

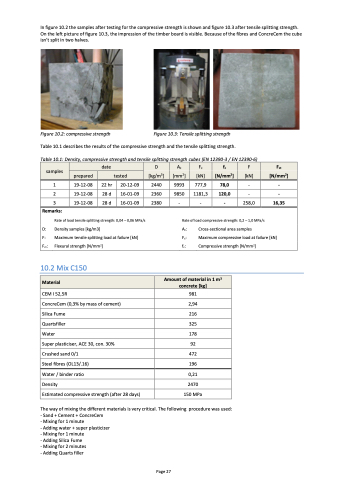

In figure 10.2 the samples after testing for the compressive strength is shown and figure 10.3 after tensile splitting strength. On the left picture of figure 10.3, the impression of the timber board is visible. Because of the fibres and ConcreCem the cube isn’t split in two halves.

Figure 10.2: compressive strength Figure 10.3: Tensile splitting strength

Table 10.1 describes the results of the compressive strength and the tensile splitting strength.

Table 10.1: Density, compressive strength and tensile splitting strength cubes (EN 12390-3 / EN 12390-6)

samples

date

D

Ac

Fc

fc

F

Fct

prepared

tested

[kg/m3]

[mm2]

[kN]

[N/mm2]

[kN]

[N/mm2]

1 19-12-08

2 19-12-08

3 19-12-08

Remarks:

22 hr 28 d 28 d

20-12-09 16-01-09 16-01-09

2440

2360

2380 -

777,9 78,0 - - 1181,3 120,0 - -

9993 9850

- - 258,0

16,35

Rate of load tensile splitting strength: 0,04 – 0,06 MPa/s D: Density samples [kg/m3]

F: Maximum tensile splitting load at failure [kN]

Fct: Flexural strength [N/mm2]

10.2 Mix C150

CEM I 52,5R

ConcreCem (0,3% by mass of cement)

Silica Fume

Quartsfiller

Water

Super plasticiser, ACE 30, con. 30%

Crushed sand 0/1

Steel fibres (OL13/.16)

Water / binder ratio

Density

Estimated compressive strength (after 28 days)

Rate of load compressive strength: 0,2 – 1,0 MPa/s

Ac: Cross-sectional area samples

Fc: Maximum compressive load at failure [kN] fc: Compressive strength [N/mm2]

981 2,94 216 325 178 92 472 196 0,21 2470 150 MPa

Material

Amount of material in 1 m3 concrete [kg]

The way of mixing the different materials is very critical. The following procedure was used: - Sand + Cement + ConcreCem

- Mixing for 1 minute

- Adding water + super plasticizer

- Mixing for 1 minute - Adding Silica Fume

- Mixing for 2 minutes - Adding Quarts filler

Page 27