Page 61 - MASHRAE 35th Anniversary

P. 61

relative humidity of ambient air and drying air were measured using hygrometer. The air speed at the outlet of the drying cabinet was measured using anemometer. In order to ensure that all experiments are performed correctly, we use the ASHRAE Standard 108 as the guiding principle for measurement and experiment setup guidelines.

Figure 3: Diagram of measuring point

Performance of TSDS

The overall efficiency of TSDS is defined as the heat energy gained by the drying air to the solar energy input on the solar collector, as given by Eq. (1).

The door must be facing north, so that direct sunlight cannot fall on the sensor when the door is opened.

Tilt angle of the collector during testing shall be between 30° to 60° unless specified by manufacturer of the collector.

RESULTS AND DISCUSSION

30.00 27.60 25.00

20.00 16.28 15.00 10.19

10.00 5.00 0.00

Water

25.20

14.42

Efficiency of Collector

24.23

12.26

6.75

1.88 1.77

2468

Quantity of collector

Ethanol R134a R600a

23.81

7.84 2.40 2.05

11.32 6.17

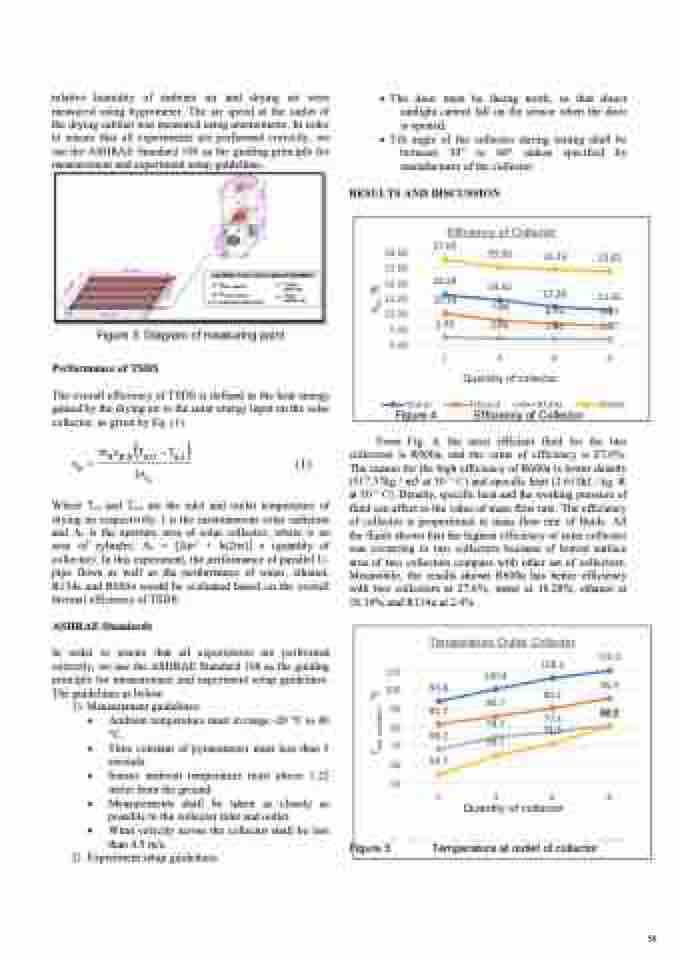

Figure 4 Efficiency of Collector

m c T T a p,a a,o a,i

s IAc

From Fig. 4, the most efficient fluid for the two collectors is R600a, and the value of efficiency is 27.6%. The reason for the high efficiency of R600a is lower density (517.37kg / m3 at 50 ° C) and specific heat (2.615kJ / kg. K at 50 ° C). Density, specific heat and the working pressure of fluid can affect to the value of mass flow rate. The efficiency of collector is proportional to mass flow rate of fluids. All the fluids shown that the highest efficiency of solar collector was occurring in two collectors because of lowest surface area of two collectors compare with other set of collectors. Meanwhile, the results shown R600a has better efficiency with two collectors at 27.6%, water at 16.28%, ethanol at 10.19% and R134a at 2.4% .

Where Ta,i and Ta,o are the inlet and outlet temperature of drying air respectively. I is the instantaneous solar radiation and Ac is the aperture area of solar collector, where is an area of cylinder, Ac = [2r2 + h(2r)] x (quantity of collector). In this experiment, the performance of parallel U- pipe flows as well as the performance of water, ethanol, R134a and R600a would be evaluated based on the overall thermal efficiency of TSDS.

ASHRAE Standards

In order to ensure that all experiments are performed correctly, we use the ASHRAE Standard 108 as the guiding principle for measurement and experiment setup guidelines. The guidelines as below:

1) Measurement guidelines:

Ambient temperature must in range -20 °C to 40

°C.

Time constant of pyranometer must less than 5

seconds.

Sensor ambient temperature must above 1.25

meter from the ground.

Measurements shall be taken as closely as

possible to the collector inlet and outlet.

Wind velocity across the collector shall be less

than 4.5 m/s.

2) Experiment setup guidelines:

Figure 5

Water

Ethanol

R134a

R600a

110

100

90

80

70 60 50

93.8

81.7 68.2

54.7

85.7 74.7 64.7

95.4 90.2

Temperature Outlet Collector

106.2 100.4

110.2

80.82 71.3

77.3

2468

Quantity of collector

3

Temperature at outlet of collector

Tout collector , °C C, %