Page 4 - Demo

P. 4

S

MANUFACTURING MATERIAL

Manufacturing Materials.

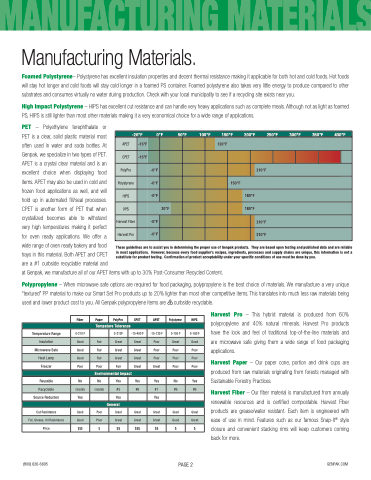

Foamed Polystyrene– Polystyrene has excellent insulation properties and decent thermal resistance making it applicable for both hot and cold foods. Hot foods will stay hot longer and cold foods will stay cold longer in a foamed PS container. Foamed polystyrene also takes very little energy to produce compared to other substrates and consumes virtually no water during production. Check with your local municipality to see if a recycling site exists near you.

High Impact Polystyrene – HIPS has excellent cut resistance and can handle very heavy applications such as complete meals. Although not as light as foamed PS, HIPS is still lighter than most other materials making it a very economical choice for a wide range of applications.

PET – Polyethylene terephthalate or

PET is a clear, solid plastic material most

often used in water and soda bottles. At

Genpak, we specialize in two types of PET.

APET is a crystal clear material and is an

excellent choice when displaying food

items. APET may also be used in cold and

frozen food applications as well, and will

hold up in automated fill/seal processes.

CPET is another form of PET that when

crystallized becomes able to withstand

very high temperatures making it perfect

for oven ready applications. We offer a

wide range of oven ready bakery and food

trays in this material. Both APET and CPET

are a #1 curbside recyclable material and

at Genpak, we manufacture all of our APET items with up to 30% Post-Consumer Recycled Content.

Polypropylene – When microwave safe options are required for food packaging, polypropylene is the best choice of materials. We manufacture a very unique “textured” PP material to make our Smart Set Pro products up to 20% lighter than most other competitive items. This translates into much less raw materials being

-20°F 0°F 50°F 100°F 150°F 200°F 250°F 300°F 350°F 400°F

APET

-15°F

120°F

CPET

-15°F

PolyPro

-0°F

210°F

Polystyrene

-0°F

150°F

HIPS

-0°F

180°F

OPS

20°F

180°F

Harvest Fiber

-0°F

210°F

Harvest Pro

-0°F

210°F

used and lower product cost to you. All Genpak polypropylene items are

curbside recyclable.

Harvest Pro – This hybrid material is produced from 60% polypropylene and 40% natural minerals. Harvest Pro products have the look and feel of traditional top-of-the-line materials and are microwave safe giving them a wide range of food packaging applications.

Harvest Paper – Our paper cone, portion and drink cups are produced from raw materials originating from forests managed with Sustainable Forestry Practices.

Harvest Fiber – Our fiber material is manufactured from annually renewable resources and is certified compostable. Harvest Fiber products are grease/water resistant. Each item is engineered with ease of use in mind. Features such as our famous Snap-It® style closure and convenient stacking rims will keep customers coming back for more.

These guidelines are to assist you in determining the proper use of Genpak products. They are based upon testing and published data and are reliable in most applications. However, because every food supplier’s recipes, ingredients, processes and supply chains are unique, this information is not a substitute for product testing. Confirmation of product acceptability under your specific conditions of use must be done by you.

Fiber

Paper

PolyPro

CPET

APET

Polystyrene

HIPS

Tempature Tolerance

Temperature Range

0-210 F

0-210F

-15-400 F

-15-120 F

0-150 F

0-180 F

Insulation

Good

Fair

Great

Great

Poor

Great

Good

Microwave Safe

Good

Fair

Great

Great

Poor

Poor

Poor

Heat Lamp

Good

Fair

Great

Great

Poor

Poor

Poor

Freezer

Poor

Poor

Fair

Great

Great

Poor

Poor

Environmental Impact

Reusable

No

No

Yes

Yes

Yes

No

Yes

Recyclable

Compostable

Compostable

#5

#6

#1

#6

#6

Source Reduction

Yes

Yes

Yes

General

Cut Resistance

Good

Poor

Great

Great

Great

Good

Great

Fat, Grease, Oil Resistance

(800) 626-6695

PAGE 2

GENPAK.COM

Good

Poor

Great

Great

Great

Good

Great

Price

$$$

$

$$

$$$

$$

$

$