Page 64 - Designing for Zero Carbon-Volume 2_Case Studies of All-Electric Multifamily Residential Buildings

P. 64

CASE STUDY NO. 3 VERA CRUZ VILLAGE

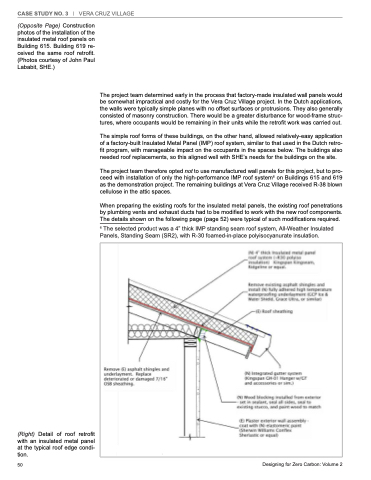

(Opposite Page) Construction photos of the installation of the insulated metal roof panels on Building 615. Building 619 re- ceived the same roof retrofit. (Photos courtesy of John Paul Lababit, SHE.)

The project team determined early in the process that factory-made insulated wall panels would be somewhat impractical and costly for the Vera Cruz Village project. In the Dutch applications, the walls were typically simple planes with no offset surfaces or protrusions. They also generally consisted of masonry construction. There would be a greater disturbance for wood-frame struc- tures, where occupants would be remaining in their units while the retrofit work was carried out.

The simple roof forms of these buildings, on the other hand, allowed relatively-easy application of a factory-built Insulated Metal Panel (IMP) roof system, similar to that used in the Dutch retro- fit program, with manageable impact on the occupants in the spaces below. The buildings also needed roof replacements, so this aligned well with SHE’s needs for the buildings on the site.

The project team therefore opted not to use manufactured wall panels for this project, but to pro- ceed with installation of only the high-performance IMP roof system6 on Buildings 615 and 619 as the demonstration project. The remaining buildings at Vera Cruz Village received R-38 blown cellulose in the attic spaces.

When preparing the existing roofs for the insulated metal panels, the existing roof penetrations by plumbing vents and exhaust ducts had to be modified to work with the new roof components. The details shown on the following page (page 52) were typical of such modifications required.

6 The selected product was a 4” thick IMP standing seam roof system, All-Weather Insulated Panels, Standing Seam (SR2), with R-30 foamed-in-place polyisocyanurate insulation.

(Right) Detail of roof retrofit with an insulated metal panel at the typical roof edge condi- tion.

50

Designing for Zero Carbon: Volume 2