Page 225 - ro membanes

P. 225

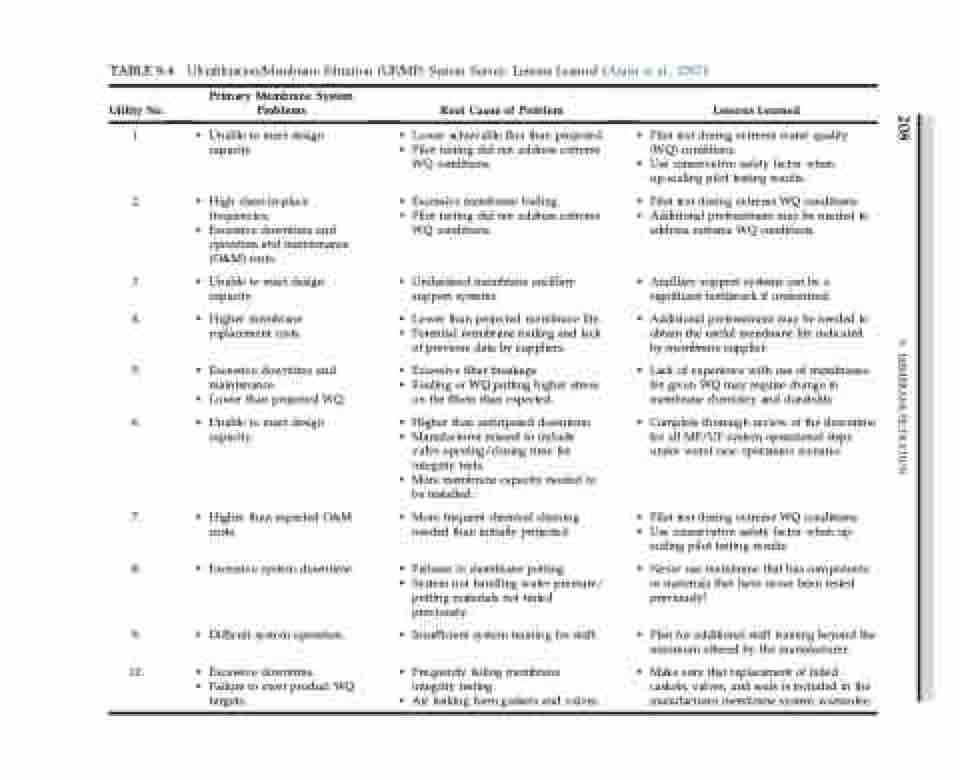

Ultrafiltration/Membrane Filtration (UF/MF) System Survey: Lessons Learned (Atassi et al., 2007)

TABLE 9.4

Root Cause of Problem

Primary Membrane System Problems

Utility No.

• Lower achievable flux than projected.

• Unable to meet design

1.

• Higher than anticipated downtime.

• Unable to meet design

6.

• Manufacturer missed to include

• More membrane capacity needed to

integrity tests.

be installed.

• Failures in membrane potting.

• Excessive system downtime.

8.

• System not handling water pressure/

• Insufficient system training for staff.

• Difficult system operation.

9.

208

9. MEMBRANE FILTRATION

Lessons Learned

address extreme WQ conditions.

• Ancillary support systems can be a

• Undersized membrane ancillary

• Unable to meet design

significant bottleneck if undersized.

by membrane supplier.

of previous data by suppliers.

scaling pilot testing results.

• Pilot test during extreme water quality

(WQ) conditions.

• Pilot testing did not address extreme

capacity

• Use conservative safety factor when up-scaling pilot testing results.

WQ conditions.

• Pilot test during extreme WQ conditions.

• Excessive membrane fouling.

• High clean-in-place

2.

• Additional pretreatment may be needed to

• Pilot testing did not address extreme

WQ conditions.

• Excessive downtime and

• Additional pretreatment may be needed to

• Lower than projected membrane life.

support systems.

capacity.

obtain the useful membrane life indicated

• Potential membrane fouling and lack

• Lack of experience with use of membranes

• Excessive fiber breakage.

• Excessive downtime and

5.

for given WQ may require change in

• Fouling or WQ putting higher stress

maintenance.

membrane chemistry and durability

on the fibers than expected.

• Lower than projected WQ.

capacity.

under worst case operations scenario.

valve opening/closing time for

• Pilot test during extreme WQ conditions.

• More frequent chemical cleaning

• Higher than expected O&M

7.

• Use conservative safety factor when up-

needed than initially projected.

costs.

• Never use membrane that has components

or materials that have never been tested

minimum offered by the manufacturer.

previously.

• Make sure that replacement of failed

• Frequently failing membrane

• Excessive downtime.

10.

caskets, valves, and seals is included in the

• Complete thorough review of the downtime for all MF/UF system operational steps

• Plan for additional staff training beyond the

previously!

potting materials not tested

manufacturer membrane system warrantee.

• Air leaking form gaskets and valves.

integrity testing.

• Failure to meet product WQ

targets.

frequencies;

operation and maintenance

(O&M) costs.

• Higher membrane

replacement costs.

3.

4.