Page 91 - TeeJet Catalog

P. 91

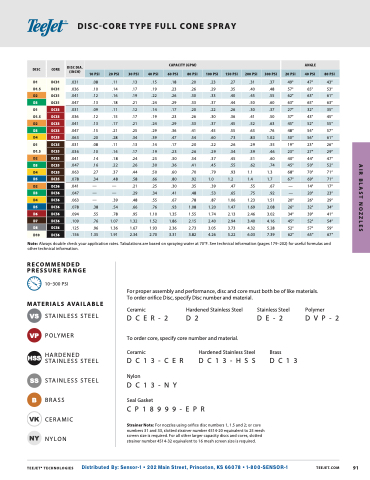

DISC CORE

D1 DC31 D1.5 DC31 D2 DC31 D3 DC31 D1 DC33 D1.5 DC33

D2 DC33

D3 DC33

D4 DC33

D1 DC35 D1.5 DC35

D2 DC35

D3 DC35

D4 DC35

D5 DC35

D2 DC56

D3 DC56

D4 DC56

D5 DC56

D6 DC56

D7 DC56

D8 DC56

D10 DC56

DISC DIA. (INCH)

CAPACITY (GPM)

ANGLE

40 PSI

47° 65° 63° 65°

32° 43° 52° 54° 56°

23° 27° 44° 50° 70° 69°

DISC-CORE TYPE FULL CONE SPRAY

10 PSI

20 PSI

.11 .14 .16 .18

.11 .15 .17 .21 .28

.11 .14 .18 .22 .37 .48

30 PSI

.13 .17 .19 .21

.12 .17 .21 .25 .34

.13 .17 .24 .26 .44 .58

40 PSI

.15 .19 .22 .24

.14 .19 .24 .29 .39

.14 .19 .25 .30 .50 .66

.25 .34 .55 .76

1.10 1.52 1.93 2.70

60 PSI

.18 .23 .26 .29

.17 .23 .29 .36 .47

.17 .23 .30 .36 .60 .80

.30 .41 .67 .93

1.35 1.86 2.36 3.31

80 PSI

.20 .26 .30 .33

.20 .26 .33 .41 .54

.20 .26 .34 .41 .70 .92

.35 .48 .78

1.08 1.55 2.15 2.73 3.82

100 PSI

.23 .29 .33 .37

.22 .30 .37 .45 .60

.22 .29 .37 .45 .79

1.0

.39 .53 .87

1.20 1.74 2.40 3.05 4.26

150 PSI

.27 .35 .40 .44

.26 .36 .45 .55 .73

.26 .34 .45 .55 .93

1.2

.47

.65 1.06 1.47 2.13 2.94 3.73 5.22

200 PSI

.31 .40 .45 .50

.30 .41 .52 .63 .83

.29 .39 .51 .62

1.1 1.4

.55

.75 1.23 1.69 2.46 3.40 4.32 6.03

300 PSI

.37 .48 .55 .60

.37 .50 .63 .76

1.02

.35 .46 .60 .74

20 PSI

49° 57° 62° 63°

27° 37° 45° 48° 50°

19° 23° 40° 45°

80 PSI

43° 53° 61° 63°

35° 45° 55° 57° 61°

26° 29° 47° 52° 71° 71°

17° 23° 29° 34° 41° 54° 59° 67°

.031 .08 .036 .10 .041 .12 .047 .13

.031 .09 .036 .12 .041 .13 .047 .15 .063 .20

.031 .08 .036 .10 .041 .14 .047 .16 .063 .27 .078 .34

1.3 68° 1.7 67°

AIR BLAST NOZZLES

.041 — — .21 .047 — — .29

.67 — 14° .92 — 20°

.063 — .39 .078 .38 .54 .094 .55 .78 .109 .76 1.07 .125 .96 1.36 .156 1.35 1.91

.48 .66 .95

1.32 1.67 2.34

1.51 20° 2.08 26° 3.02 34° 4.16 45° 5.28 52° 7.39 62°

26° 32° 39° 52° 57° 65°

Note: Always double check your application rates. Tabulations are based on spraying water at 70°F. See other technical information.

technical information (pages 179–202) for

useful formulas and

RECOMMENDED PRESSURE RANGE

10–300 PSI

MATERIALS AVAILABLE

VS STAINLESS STEEL

VP POLYMER HSS HARDENED

STAINLESS STEEL SS STAINLESS STEEL

B BRASS VK CERAMIC NY NYLON

For proper assembly and performance, disc and core must both be of like materials. To order orifice Disc, specify Disc number and material.

TEEJET® TECHNOLOGIES

Distributed By: Sensor-1 • 202 Main Street, Princeton, KS 66078 • 1-800-SENSOR-1

TEEJET.COM 91

Ceramic Hardened Stainless Steel DCER-2 D2

To order core, specify core number and material.

Ceramic Hardened Stainless Steel DC13-CER DC13-HSS DC13

Nylon DC13-NY

Seal Gasket CP18999-EPR

Strainer Note: For nozzles using orifice disc numbers 1, 1.5 and 2; or core numbers 31 and 33, slotted strainer number 4514-20 equivalent to 25 mesh screen size is required. For all other larger capacity discs and cores, slotted strainer number 4514-32 equivalent to 16 mesh screen size is required.

Stainless Steel Polymer DE-2 DVP-2

Brass