Page 159 - Dickey-john Catalog

P. 159

A DIVISION OF TSI®

®

Service Parts

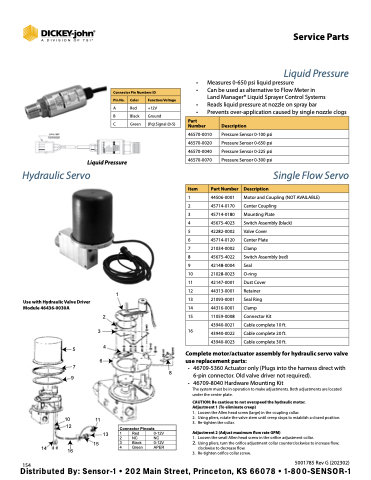

Connector Pin Numbers ID

Pin No.

Color

Function/Voltage

A B C

Red Black Green

+12V

Ground

(Pq) Signal (0-5)

Liquid Pressure

• Measures 0-650 psi liquid pressure

• Can be used as alternative to Flow Meter in

Land Manager® Liquid Sprayer Control Systems

• Reads liquid pressure at nozzle on spray bar

• Prevents over-application caused by single nozzle clogs

Part Number

Description

Liquid Pressure

46570-0010

46570-0020

46570-0040

46570-0070

Pressure Sensor 0-100 psi

Pressure Sensor 0-650 psi

Pressure Sensor 0-225 psi

Pressure Sensor 0-300 psi

Hydraulic Servo

Single Flow Servo

Motor and Coupling (NOT AVAILABLE)

Center Coupling

Mounting Plate

Switch Assembly (black)

Valve Cover

Center Plate

Clamp

Switch Assembly (red)

Seal

O-ring

Dust Cover

Retainer

Seal Ring

Clamp

Connector Kit

Cable complete 10 ft.

Cable complete 20 ft.

Cable complete 30 ft.

Item

Part Number

Description

Use with Hydraulic Valve Driver Module 46436-0030A

1

4

1 44506-0001

2 45714-0170

3 45714-0180

4 45675-4023

5 42282-0002

6 45714-0120

7 21034-0002

8 45675-4022

9 42148-0004

10 21028-0023

11 42147-0001

12 44313-0001

13 21093-0001

14 44316-0001

15 11059-0008

3

6

16

43940-0021

43940-0022

43940-0023

2

Co n n e c t o r P i n o u t s

1 Red 0-12V

2 NC NC

3 Black 0-12V

4 Green APER

14

154

10 11

13

15

16

5

7 9

Complete motor/actuator assembly for hydraulic servo valve use replacement parts:

Distributed By: Sensor-1 • 202 Main Street,

Princeton, KS 66078 • 1-800-SENSOR-1

8

•

•

46709-5360 Actuator only (Plugs into the harness direct with

6-pin connector. Old valve driver not required).

46709-8040 Hardware Mounting Kit

The system must be in operation to make adjustments. Both adjustments are located under the center plate.

CAUTION: Be cautious to not overspeed the hydraulic motor.

Adjustment 1 (To eliminate creep)

1. Loosen the Allen head screw (large) in the coupling collar.

2. Using pliers, rotate the valve stem until creep stops to establish a closed position. 3. Re-tighten the collar.

Adjustment 2 (Adjust maximum flow rate GPM)

1. Loosen the small Allen head screw in the orifice adjustment collar.

2. Using pliers, turn the orifice adjustment collar counterclockwise to increase flow;

clockwise to decrease flow.

3. Re-tighten orifice collar screw.

5001785 Rev G (202302)

12