Page 43 - Wilger Catalog

P. 43

P L U M B I N G

Retrofitting & Flange Compatibility

Fittings available for complementing any sort of sprayer boom & more.

Can bE OUtfittED fOR: 1” sch40 Pipe (1.315” OD)

Any 1” Flanged Fittings Wilger Stainless Tubing Case Thin Wall Stainless

Compatible with other 1” Flange Fittings

2-1/32” Flange Surface

1-3/8” Flange Seal

1” Inside Diameter

Compact & Robust Sweep Fittings

Sweep fittings reduce turbulence & pressure loss, producing a sprayer that is capable of higher flow rates with less

A COMBO-RATE boom end flush valve with double-down turret, equipped with PWM solenoid.

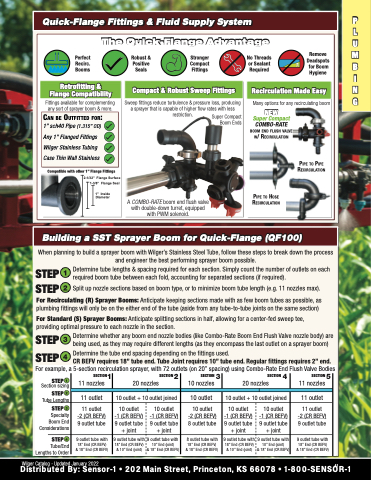

Building a SST Sprayer Boom for Quick-Flange (QF100)

restriction.

Super Compact Boom Ends

hen planning to build a sprayer boom with Wilger’s Stainless Steel Tube, follow these steps to break down the process and engineer the best performing sprayer boom possible.

STEP 1 Determine tube lengths & spacing required for each section. Simply count the number of outlets on each required boom tube between each fold, accounting for separated sections (if required).

STEP 2 Split up nozzle sections based on boom type, or to minimize boom tube length (e.g. 11 nozzles max). r Recirculating (R) Sprayer Booms: Anticipate keeping sections made with as few boom tubes as possible, as

plumbing fittings will only be on the either end of the tube (aside from any tube-to-tube joints on the same section)

For Standard (S) Sprayer Booms: Anticipate splitting sections in half, allowing for a center-fed sweep tee, providing optimal pressure to each nozzle in the section.

STEP 3 Determine whether any boom end nozzle bodies (like Combo-Rate Boom End Flush Valve nozzle body) are being used, as they may require different lengths (as they encompass the last outlet on a sprayer boom)

STEP 4 Determine the tube end spacing depending on the fittings used.

CR BEFV requires 18” tube end. Tube Joint requires 10” tube end. Regular fittings requires 2” end.

For example, a 5-section recirculation sprayer, with 72 outlets (on 20” spacing) using Combo-Rate End Flush Valve Bodies

Recirculation Made Easy

Many options for any recirculating boom

NEW Super Compact COMBO-RATE boom end flush valve w/ ReciRculation

PiPe to PiPe ReciRculation

PiPe to hose ReciRculation

W

Fo

Quick-Flange Fittings & Fluid Supply System

Perfect Recirc. Booms

Robust & Positive Seals

Stronger Compact Fittings

No Threads or Sealant Required

Remove Deadspots for Boom Hygiene

The Quick-Flange Advantage

STEP 1 Section sizing

STEP 2 Tube Lengths

STEP 3 Specialty Boom End Considerations

STEP 4 Tube/End Lengths to Order

SECtIon1 11 nozzles

20 nozzles

SECtIon 2

SECtIon 3 10 nozzles

SECtIon 4 20 nozzles

SECtIon 5 11 nozzles

11 outlet

11 outlet -2 (CR BEFV) 9 outlet tube

10 outlet + 10 outlet joined

10 outlet -1 (CR BEFV) 9 outlet tube + joint

10 outlet -1 (CR BEFV) 9 outlet tube + joint

10 outlet

10 outlet -2 (CR BEFV) 8 outlet tube

10 outlet + 10 outlet joined

10 outlet -1 (CR BEFV) 9 outlet tube + joint

10 outlet -1 (CR BEFV) 9 outlet tube + joint

11 outlet

11 outlet -2 (CR BEFV) 9 outlet tube

9 outlet tube with 18” End (CR BEFV) & 18” End (CR BEFV)

9 outlet tube with 18” End (CR BEFV) & 10” End (joint)

9 outlet tube with 10” End (joint)

& 18” End (CR BEFV)

8 outlet tube with 18” End (CR BEFV) & 18” End (CR BEFV)

9 outlet tube with 18” End (CR BEFV) & 10” End (joint)

9 outlet tube with 10” End (joint)

& 18” End (CR BEFV)

9 outlet tube with 18” End (CR BEFV) & 18” End (CR BEFV)

Wilger Catalog - Updated January 2022

43

Distributed By: Sensor-1 • 202 Main Street, Princeton, KS 66078 • 1-800-SENSOR-1