Page 88 - Demo

P. 88

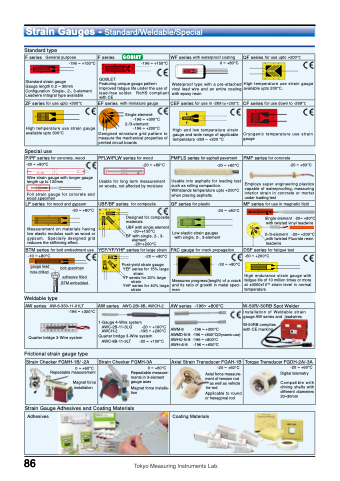

Strain Gauges - Standard/Weldable/Special

Standard type

F series General purpose F series GOBLET WF series with waterproof coating QF series for use upto +200°C

0 ~ +80°C

Waterproof type with a pre-attached vinyl lead wire and an entire coating with epoxy resin

-196 ~ +150°C

Standard strain gauge

Gauge length 0.2 ~ 30mm Configuration Single-, 2-, 3-element Leadwire integral type available

-196 ~ +150°C

GOBLET

Featuring unique gauge pattern Improved fatigue life under the use of lead-free solder. RoHS compliant with CE

ZF series for use upto +300°C EF series with miniature gauge CEF series for use in -269 to +200°C CF series for use down to -269°C

High temperature use strain gauge available upto 200°C.

Single element: -196 ~ +300°C

2-/3-element:

-196 ~ +200°C

Designed miniature grid pattern to measure the mechanical properties of printed circuit boards

High temperature use strain gauge available upto 300°C

High and low temperature strain gauge and wide range of applicable temperature -269 ~ +200 °C

Cryogenic temperature use strain gauge

Special use

P/PF series for concrete, wood PFLW/PLW series for wood PMFLS series for asphalt pavement PMF series for concrete

-20 ~ +80°C

Wire strain gauge with longer gauge

Foil strain gauge for concrete and wood specimen

-20 ~ +80°C

Usable for long term measurement on woods, not affected by moisture

-20 ~ +60°C

Usable into asphalts for loading test such as rolling compaction. Withstands temperature upto +200°C when placing asphalts.

-20 ~ +60°C

Employs super engineering plastics capable of waterproofing, measuring interior strain in concrete or mortar under loading test

30

length up to 120mm

LF series for wood and gypsum UBF/BF series for composite GF series for plastic MF series for use in magnetic field

-20 ~ +80°C

Measurement on materials having low elastic modulus such as wood or gypsum. Specially designed grid reduces the stiffening effect.

Designed for composite materials

UBF with single element -30~+150°C

BF with single, 2-, 3- element

-20~+200°C

BTM series for bolt embedment use YEF/YF/YHF series for large strain FAC gauge for crack propagation DSF series for fatigue test

-20 ~ +80°C

Low elastic strain gauges with single, 2-, 3-element

-10 ~ +80°C

gauge lead hole drilled

bolt specimen

adhesive filled BTM embedded

-60 ~ +200°C

High endurance strain gauge with fatigue life of 10 million times or more at ±3000x10-6 strain level in normal temperature

-30 ~ +80°C

Measures progress(length) of a crack and its ratio of growth in metal speci- men

Weldable type

-20 ~ +80°C

Post-yield strain gauge YEF series for 15% large

strain

YF sereis for 20% large

strain

YHF series for 40% large

strain

AW series AW-6-350-11-01LT AW series AWC-2B/-8B, AWCH-2 AW series -196~ +800°C W-50R/-50RB Spot Welder

-196 ~ +300°C

Quarter bridge 3-Wire system

Installation of Weldable strain gauge AW series and leadwires

W-50RB complies with CE marking.

1-Gauge 4-Wire system AWC-2B-11-3LQ -20 ~ +100°C AWCH-2 -196 ~ +200°C

Quarter bridge 3-Wire system AWC-8B-11-3LT -20 ~ +100°C

Frictional strain gauge type

Strain Checker FGMH-1B/ -2A Strain Checker FGMH-3A Axial Strain Transducer FGAH-1B Torque Transducer FGDH-2A/-3A

AWM-8 -196 ~ +300°C

AWMD-5/-8 -196~+800°C(Dynamicuse) AWHU-5/-8 -196 ~ +800°C

AWH-4/-8 -196 ~ +650°C

-20 ~ +60°C

Axial force measure- ment of tension rod

as well as vehicle tie-rod

Applicable to round or hexagonal rod

-20 ~ +60°C Digital telemetry

Compatible with driving shafts with different diameters 20~30mm

0 ~ +60°C Repeatable measurement

Magnet force installation

0 ~ +60°C Repeatable measure-

ments in 3-element gauge axes

Magnet force installa- tion

Strain Gauge Adhesives and Coating Materials

Adhesives

Coating Materials

Single element -20~ +80°C with twisted vinyl leadwire

2-/3-element -20~ +200°C with twisted Fluoride resin leadwire

86