Page 155 - PCMI Journal December 2020

P. 155

31

BP.

Dry Film Resist Control Topics in Photo Chemical Milling Processes Presented by: Sean Hill, Project Manager | Eternal Technology Corporation, US 12/18/20

32

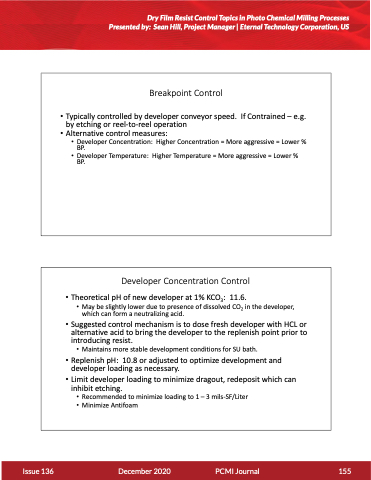

Breakpoint Control

• Typically controlled by developer conveyor speed. If Contrained – e.g. by etching or reel-to-reel operation

• Alternative control measures:

• Developer Concentration: Higher Concentration = More aggressive = Lower %

• Developer Temperature: Higher Temperature = More aggressive = Lower % BP.

Developer Concentration Control

• Theoretical pH of new developer at 1% KCO3: 11.6.

• May be slightly lower due to presence of dissolved CO2 in the developer,

• Suggested control mechanism is to dose fresh developer with HCL or alternative acid to bring the developer to the replenish point prior to introducing resist.

which can form a neutralizing acid.

• Maintains more stable development conditions for SU bath.

• Replenish pH: 10.8 or adjusted to optimize development and

developer loading as necessary.

• Limit developer loading to minimize dragout, redeposit which can inhibit etching.

• Recommended to minimize loading to 1 – 3 mils-SF/Liter • Minimize Antifoam

Issue 136 December 2020 PCMI Journal 155

16