Page 28 - bne monthly magazine October 2022

P. 28

28 I Cover story bne October 2022

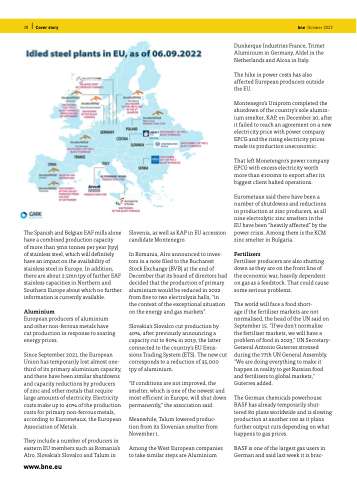

The Spanish and Belgian EAF mills alone have a combined production capacity

of more than 3mn tonnes per year (tpy) of stainless steel, which will definitely have an impact on the availability of stainless steel in Europe. In addition, there are about 2.5mn tpy of further EAF stainless capacities in Northern and Southern Europe about which no further information is currently available.

Aluminium

European producers of aluminium and other non-ferrous metals have cut production in response to soaring energy prices.

Since September 2021, the European Union has temporarily lost almost one- third of its primary aluminium capacity, and there have been similar shutdowns and capacity reductions by producers

of zinc and other metals that require large amounts of electricity. Electricity costs make up to 40% of the production costs for primary non-ferrous metals, according to Eurometaux, the European Association of Metals.

They include a number of producers in eastern EU members such as Romania’s Alro, Slovakia’s Slovalco and Talum in

www.bne.eu

Slovenia, as well as KAP in EU accession candidate Montenegro.

In Romania, Alro announced to inves- tors in a note filed to the Bucharest Stock Exchange (BVB) at the end of December that its board of directors had decided that the production of primary aluminium would be reduced in 2022 from five to two electrolysis halls, “in the context of the exceptional situation on the energy and gas markets”.

Slovakia’s Slovalco cut production by 40%, after previously announcing a capacity cut to 80% in 2019, the latter connected to the country’s EU Emis- sions Trading System (ETS). The new cut corresponds to a reduction of 35,000 tpy of aluminium.

“If conditions are not improved, the smelter, which is one of the newest and most efficient in Europe, will shut down permanently," the association said.

Meanwhile, Talum lowered produc- tion from its Slovenian smelter from November 1.

Among the West European companies to take similar steps are Aluminium

Dunkerque Industries France, Trimet Aluminium in Germany, Aldel in the Netherlands and Alcoa in Italy.

The hike in power costs has also affected European producers outside the EU.

Montenegro’s Uniprom completed the shutdown of the country’s sole alumin- ium smelter, KAP, on December 30, after it failed to reach an agreement on a new electricity price with power company EPCG and the rising electricity prices made its production uneconomic.

That left Monetengro’s power company EPCG with excess electricity worth more than €100mn to export after its biggest client halted operations.

Eurometaux said there have been a number of shutdowns and reductions in production at zinc producers, as all nine electrolytic zinc smelters in the EU have been “heavily affected” by the power crisis. Among them is the KCM zinc smelter in Bulgaria.

Fertilisers

Fertiliser producers are also shutting down as they are on the front line of the economic war, heavily dependent on gas as a feedstock. That could cause some serious problems.

The world will face a food short-

age if the fertiliser markets are not normalised, the head of the UN said on September 15. "If we don't normalise the fertiliser markets, we will have a problem of food in 2023," UN Secretary- General Antonio Guterres stressed during the 77th UN General Assembly. "We are doing everything to make it happen in reality to get Russian food and fertilisers to global markets," Guterres added.

The German chemicals powerhouse BASF has already temporarily shut- tered 80 plans worldwide and is slowing production at another 100 as it plans further output cuts depending on what happens to gas prices.

BASF is one of the largest gas users in German and said last week it is brac-