Page 35 - Reeley 2019 Catalogue

P. 35

34

GUIDE SHOE LINER MATERIALS

Drawings are actual size and are for identification purposes only Please see our website for up to date pricing

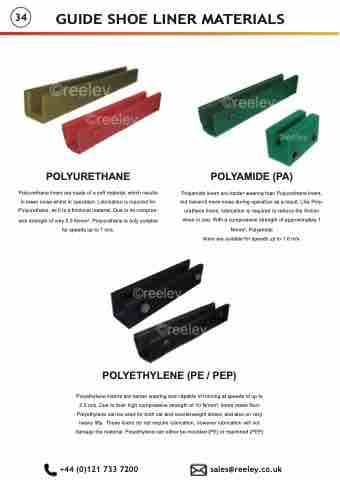

POLYURETHANE

Polyurethane liners are made of a soft material, which results in lower noise whilst in operation. Lubrication is required for Polyurethane, as it is a frictional material. Due to its compres-

sive strength of only 0.5 N/mm2, Polyurethane is only suitable for speeds up to 1 m/s.

POLYAMIDE (PA)

Polyamide liners are harder wearing than Polyurethane liners, but transmit more noise during operation as a result. Like Poly- urethane liners, lubrication is required to reduce the friction when in use. With a compressive strength of approximately 1

N/mm2, Polyamide

liners are suitable for speeds up to 1.6 m/s.

POLYETHYLENE (PE / PEP)

Polyethylene inserts are harder wearing and capable of running at speeds of up to 2.5 m/s. Due to their high compressive strength of 10 N/mm2, liners made from Polyethylene can be used for both car and counterweight shoes, and also on very heavy lifts. These liners do not require lubrication, however lubrication will not damage the material. Polyethylene can either be moulded (PE) or machined (PEP)

+44 (0)121 733 7200 sales@reeley.co.uk