Page 146 - Mike Murphy's Blog Posts

P. 146

interact with the oxygen in the air. If enough energy is output, ozone can be generated by the laser energy.

This also generates a loud cracking sound due to the extreme and rapid pressure changes in the air.

However, this ‘crack’ has nothing to do with the tattoo treatment. In fact, it is more likely to damage the skin since excessive fluences are being used.

https://youtu.be/UVeHNaEBntg

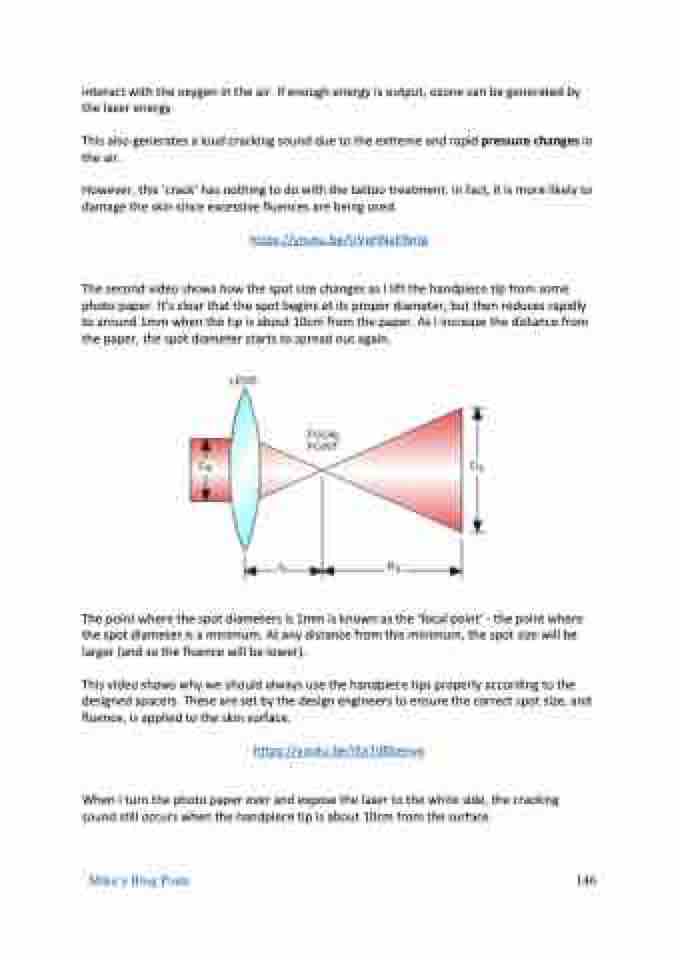

The second video shows how the spot size changes as I lift the handpiece tip from some photo paper. It’s clear that the spot begins at its proper diameter, but then reduces rapidly to around 1mm when the tip is about 10cm from the paper. As I increase the distance from the paper, the spot diameter starts to spread out again.

The point where the spot diameters is 1mm is known as the ‘focal point’ - the point where the spot diameter is a minimum. At any distance from this minimum, the spot size will be larger (and so the fluence will be lower).

This video shows why we should always use the handpiece tips properly according to the designed spacers. These are set by the design engineers to ensure the correct spot size, and fluence, is applied to the skin surface.

https://youtu.be/iEa7dBbenvo

When I turn the photo paper over and expose the laser to the white side, the cracking sound still occurs when the handpiece tip is about 10cm from the surface.

Mike’s Blog Posts 146