Page 98 - Avtron Encoders Catalog

P. 98

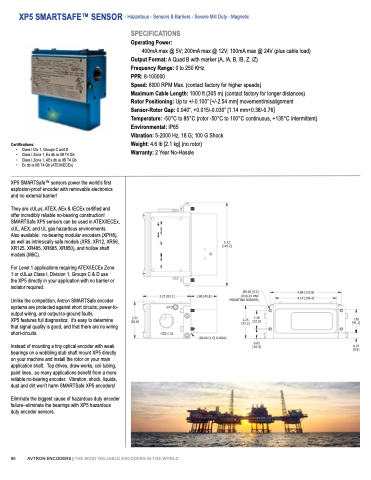

XP5 SMARTSAFETM SENSOR - - - - Hazardous - - - - Sensors & Barriers - - - - Severe Mill Duty - - - - Magnetic

Certifications:

• • Class Class I I I I Div 1 1 Groups C C C and D D • • • Class Class Class I I I I I I I Zone Zone 1 1 1 Ex Ex db db ia ia IIB IIB T4 T4 Gb Gb • • • Class Class I I I I I I I I I Zone Zone 1 1 AEx db db db ia ia ia IIB IIB IIB T4 T4 T4 Gb Gb Gb • • Ex Ex Ex db db ia ia IIB IIB T4 T4 Gb Gb (ATEX/IECEx)

XP5 SMARTSafeTM sensors power the world’s first explosion-proof encoder with removable electronics and no external barrier!

They are cULus ATEX AEx & IECEx certified and offer incredibly reliable no-bearing construction! SMARTSafe XP5 sensors can be be used in in in ATEX/IECEx cUL AEX and UL UL gas hazardous environments Also available: no-bearing modular encoders (XPH8) as as well as as intrinsically safe models (XR5 XR12 XR12 XR56 XR125 XR485 XR685 XR850) and hollow shaft models (M6C) For Level 1 1 1 applications requiring ATEX/IECEx Zone 1 1 1 or or cULus Class I I Division 1 1 1 Groups C C C & D D use the XP5 directly in your application with no barrier or or or isolator required Unlike the competition Avtron SMARTSafe encoder systems are protected against short circuits power-to- output output wiring and output-to-ground faults XP5 features full diagnostics: it’s easy to to determine that that signal quality is good and that that there are no no wiring short-circuits Instead of mounting a a a a a a a tiny optical encoder with weak bearings on on on a a a a a a a a a a a wobbling stub shaft mount mount XP5 directly on on on on your your machine and install the rotor on on on on your your main application application shaft Top drives draw works coil tubing paint lines so many applications benefit from a a a a a a a a a a a a more reliable no-bearing encoder encoder Vibration shock liquids dust and dirt won’t harm SMARTSafe XP5 encoders!

Eliminate the the biggest cause of hazardous hazardous duty encoder failure--eliminate the the bearings with XP5 hazardous hazardous duty encoder sensors 95 AVTRON ENCODERS ENCODERS | THE THE MOST RELIABLE ENCODERS ENCODERS IN THE THE WORLD

SPECIFICATIONS

Operating Power:

400mA max max max @ @ @ 5V 200mA max max max @ @ @ 12V 100mA max max max @ @ @ 24V (plus cable load) Output Format: A A A A A A Quad B B B with marker (A /A B B B /B Z Z /Z)

Frequency Range: 0 0 to 250 KHz

PPR: 8-100000

Speed: 6000 RPM Max Max (contact factory for higher speeds)

Maximum Cable Length: 1000 ft (305 m) (contact (contact factory factory for for longer distances) Rotor Rotor Positioning: Up to to to to +/-0 100” [+/-2 54 mm] movement/misalignment Sensor-Rotor Gap: 0 0 0 0 0 0 0 0 0 0 0 0 0 040” +0 +0 015/-0 030” [1 14 mm+0 38/-0 76]

Temperature: -50°C -50°C to to to to 85°C (rotor -50°C -50°C to to to to 100°C continuous +135°C intermittent) Environmental: IP65

Vibration: 5-2000 Hz

18 G G 100 G G Shock

Weight: 4 6 lb [2 1 1 1 kg] (no rotor)

Warranty: 2 2 Year No-Hassle