Page 21 - One Last Turn

P. 21

out there, closing speeds did sometimes cause problems, especially with slower cars and Donohue’s 917/30.

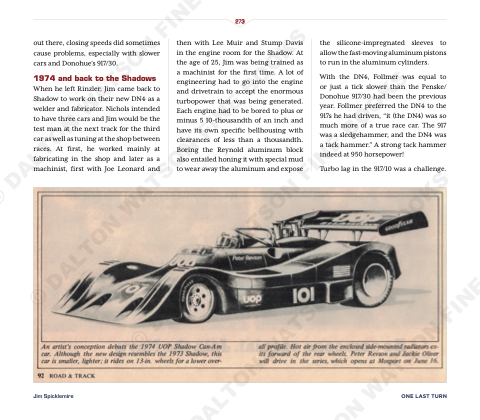

1974 and back to the Shadows

When he left Rinzler, Jim came back to Shadow to work on their new DN4 as a welder and fabricator. Nichols intended to have three cars and Jim would be the test man at the next track for the third car as well as tuning at the shop between races. At first, he worked mainly at fabricating in the shop and later as a machinist, first with Joe Leonard and

273

then with Lee Muir and Stump Davis

in the engine room for the Shadow. At the age of 25, Jim was being trained as a machinist for the first time. A lot of engineering had to go into the engine and drivetrain to accept the enormous turbopower that was being generated. Each engine had to be bored to plus or minus 5 10-thousandth of an inch and have its own specific bellhousing with clearances of less than a thousandth. Boring the Reynold aluminum block also entailed honing it with special mud to wear away the aluminum and expose

the silicone-impregnated sleeves to allow the fast-moving aluminum pistons to run in the aluminum cylinders.

With the DN4, Follmer was equal to or just a tick slower than the Penske/ Donohue 917/30 had been the previous year. Follmer preferred the DN4 to the 917s he had driven, “it (the DN4) was so much more of a true race car. The 917 was a sledgehammer, and the DN4 was a tack hammer.” A strong tack hammer indeed at 950 horsepower!

Turbo lag in the 917/10 was a challenge.

Jim Spicklemire

ONE LAST TURN

© DALTON WATSON FINE B

© DALTON WATSON FINE BOOKS © DALTON WATSON FINE BOOKS DALTON WATSON FINE BOOKS TON WATSON FINE B