Page 114 - Nicolaes Witsen & Shipbuilding in the Dutch Golden Age

P. 114

Chapter Two

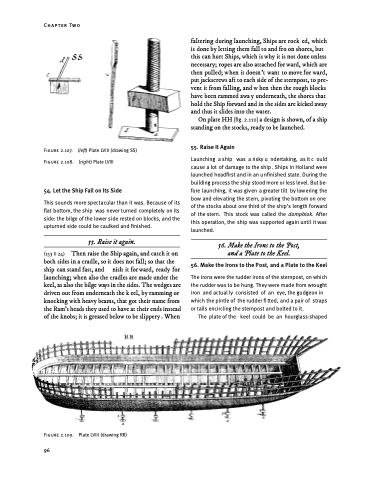

Figure 2.107. Figure 2.108.

(left) Plate LVIII (drawing SS) (right) Plate LVIII

faltering during launching, Ships are rock ed, which is done by letting them fall to and fro on shores, but this can hurt Ships, which is why it is not done unless necessary; ropes are also attached for ward, which are then pulled; when it doesn’t want to move for ward, put jackscrews aft to each side of the sternpost, to pre- vent it from falling, and w hen then the rough blocks have been rammed awa y underneath, the shores that hold the Ship forward and in the sides are kicked away and thus it slides into the water.

On plate HH [fig. 2.110] a design is shown, of a ship standing on the stocks, ready to be launched.

55. Raise It Again

Launching a ship was a risky u ndertaking, as it c ould cause a lot of damage to the ship. Ships in Holland were launched headfirst and in an unfinished state. During the building process the ship stood more or less level. But be- fore launching, it was giv en a greater tilt by low ering the bow and elevating the stern, pivoting the bottom on one of the stocks about one third of the ship’s length forward of the stern. This stock was called the dompblok. After this operation, the ship was supported again until it was launched.

56. Make the Irons to the Post, and a Plate to the Keel.

56. Make the Irons to the Post, and a Plate to the Keel

The irons were the rudder irons of the sternpost, on which the rudder was to be hung. They were made from wrought iron and actual ly consisted of an eye, the gudgeon in which the pintle of the rudder fi tted, and a pair of straps or tails encircling the sternpost and bolted to it.

The plate of the keel could be an hourglass-shaped

54. Let the Ship Fall on Its Side

This sounds more spectacular than it was. Because of its flat bottom, the ship was never t urned completely on its side: the bilge of the lower side rested on blocks, and the upturned side could be caulked and finished.

55. Raise it again.

(153 II 24) Then raise the Ship again, and catch it on both sides in a cradle, so it does not fall; so that the ship can stand fast, and nish it for ward, ready for launching; when also the cradles are made under the keel, as also the bilge ways in the sides. The wedges are driven out from underneath the k eel, by ramming or knocking with heavy beams, that got their name from the Ram’s heads they used to have at their ends instead of the knobs; it is greased below to be slippery . When

Figure 2.109. Plate LVIII (drawing RR) 96