Page 91 - Nicolaes Witsen & Shipbuilding in the Dutch Golden Age

P. 91

How Ships Are Built in Holland Today

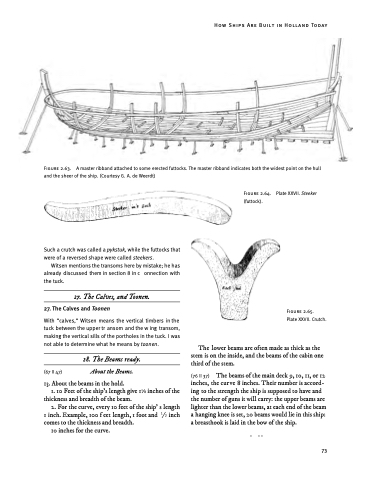

Figure 2.63. A master ribband attached to some erected futtocks. The master ribband indicates both the widest point on the hull and the sheer of the ship. (Courtesy G. A. de Weerdt)

Figure 2.64. (futtock).

Plate XXVII. Steeker

Such a crutch was called a pykstuk, while the futtocks that were of a reversed shape were called steekers.

Witsen mentions the transoms here by mistake; he has already discussed them in section 8 in c onnection with the tuck.

27. The Calves, and Toonen.

27. The Calves and Toonen

With “calves,” Witsen means the vertical timbers in the tuck between the upper tr ansom and the w ing transom, making the vertical sills of the portholes in the tuck. I was not able to determine what he means by toonen.

Figure 2.65.

Plate XXVII. Crutch.

(67 II 47)

28. The Beams ready. About the Beams.

The lower beams are often made as thick as the stem is on the inside, and the beams of the cabin one third of the stem.

(76 II 37) The beams of the main deck 9, 10, 11, or 12 inches, the cur ve 8 inches. Their number is accord- ing to the strength the ship is supposed to have and the number of guns it will carry: the upper beams are lighter than the lower beams, at each end of the beam a hanging knee is set, 20 beams would lie in this ship: a breasthook is laid in the bow of the ship.

13. About the beams in the hold.

1. 10 Feet of the ship’s length give 11⁄8 inches of the

thickness and breadth of the beam.

2. For the curve, every 10 feet of the ship’ s length

1 inch. Example, 100 f eet length, 1 foot and 1⁄2 inch comes to the thickness and breadth.

10 inches for the curve.

. ..

73