Page 167 - The ROV Manual - A User Guide for Remotely Operated Vehicles 2nd edition

P. 167

The connector must not adversely affect the application. For example, all ferrous materials (steel, etc.) should be avoided in cases where the connectors’ magnetic signature might affect the system. In extreme cases, even the nickel used under gold plating could have an effect and should be reviewed.

The physical size of the connector, its weight, ease of use (and appropriateness for the applica- tion), durability, submergence (depth) rating, field repairability, etc. should all be assessed. The use of oil-filled cables or connectors should be considered.

Ease of installation and use is especially important, so realistically appraise the technical ability of those personnel who will actually install or use the equipment. If they are inexperienced, a more “user-friendly” connector may be a better choice. And, if possible, train operators in the basics of proper connector use: Use only a little lubricant, avoid over-tightening (this is an especially com- mon and annoying problem), note acceptable cable bending radii, provide grounding wires for steel connectors in aluminum bulkheads, etc.

Splicing and repairing underwater cables and connectors, while quite simple, require some basic precautions to avoid water ingress into the electrical spaces, thus grounding the connection. See Chapter 8 for a detailed discussion of cables and connectors.

7.1.7.2 Electrohydraulic power

While the OCROV has electrical energy exclusively driving moving components, both the MSROV and WCROV typically involve some form of fluid component drive (i.e., hydraulics) for a portion or all of its moving components. On all hydraulic components, the electric circuit drives an electric motor which in turns drives a hydraulic pump at the design specifications of the pump manufac- turer. On MSROVs, this typically means that the vehicle manufacturer modifies (or directly uses) a thruster motor to turn the low-volume pump, while the WCROV manufacturer will specially design an HV motor (or design the hydraulic system around a COTS HV motor) to achieve the system’s design objective involving a large number of hydraulic components.

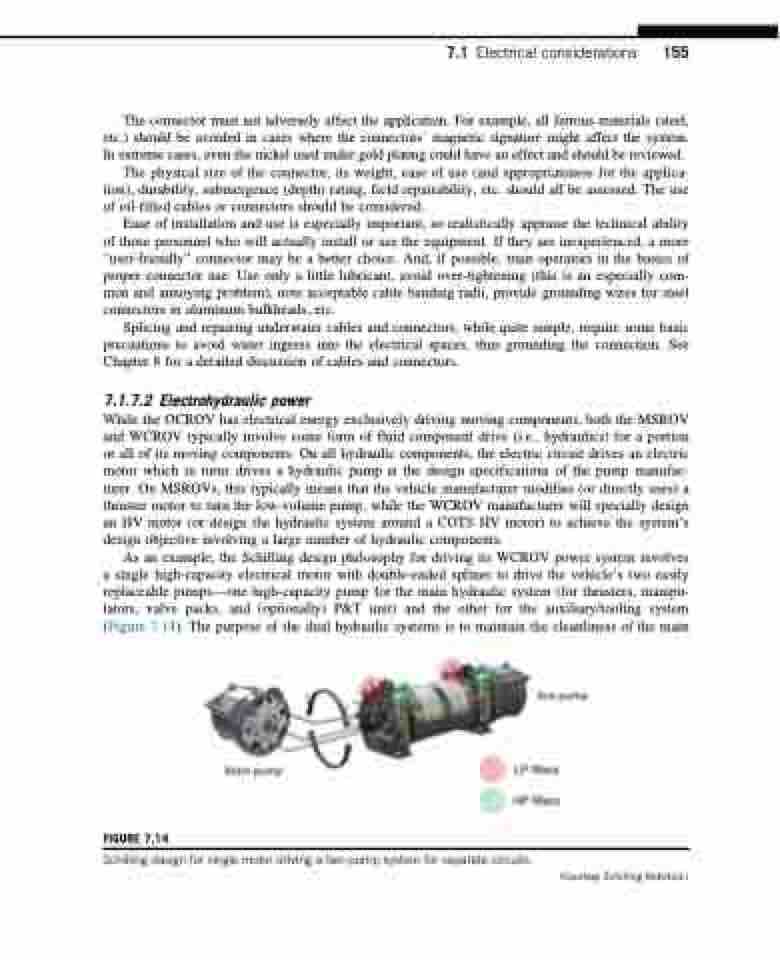

As an example, the Schilling design philosophy for driving its WCROV power system involves a single high-capacity electrical motor with double-ended splines to drive the vehicle’s two easily replaceable pumps—one high-capacity pump for the main hydraulic system (for thrusters, manipu- lators, valve packs, and (optionally) P&T unit) and the other for the auxiliary/tooling system (Figure 7.14). The purpose of the dual hydraulic systems is to maintain the cleanliness of the main

FIGURE 7.14

Schilling design for single motor driving a two-pump system for separate circuits.

7.1 Electrical considerations 155

(Courtesy Schilling Robotics.)