Page 161 - RoadCem Manual - PCT BV

P. 161

The resulting surface is cured with water until hardening.

This surfacing option gives a surface with good skid resistance but sometimes wearing resistance is reduced due to lack of full integration of the gravel material into the stabilized layer. For law intensity traffic this should not be a problem but if traffic intensity is high than we recommended that following the compaction of gravel into the stabilized layer a self levelling slurry is made from:

• • •

RoadCem (4 kg); Cement(1000 kg); Water (1000 kg).

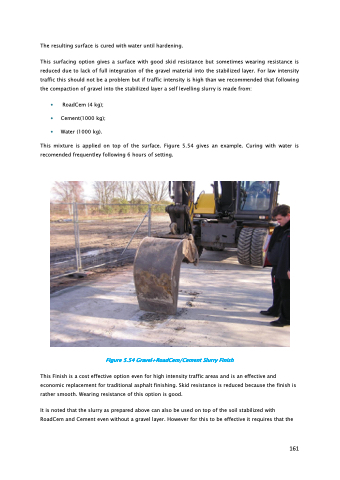

This mixture is applied on top of the surface. Figure 5.54 gives an example. Curing with water is recomended frequentley following 6 hours of setting.

Figure 5.54 Gravel+RoadCem/Cement Slurry Finish

This Finish is a cost effective option even for high intensity traffic areas and is an effective and economic replacement for traditional asphalt finishing. Skid resistance is reduced because the finish is rather smooth. Wearing resistance of this option is good.

It is noted that the slurry as prepared above can also be used on top of the soil stabilized with RoadCem and Cement even without a gravel layer. However for this to be effective it requires that the

161