Page 58 - 365411 Findley 92pp A4 PBound.pdf

P. 58

5

58

8

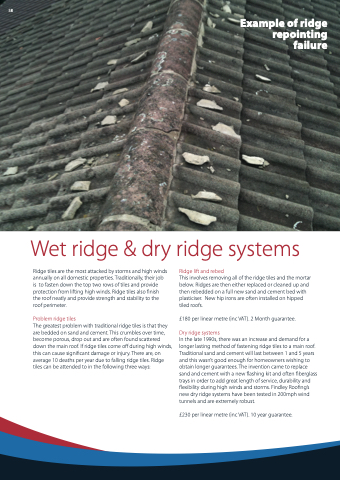

Example of ridge repointing failure

Wet ridge & dry ridge systems

Ridge tiles are the most attacked by storms and high winds annually on all domestic properties. Traditionally, their job is to fasten down the top two rows of tiles and provide protection from lifting high winds. Ridge tiles also finish the roof neatly and provide strength and stability to the roof perimeter.

Problem ridge tiles

The greatest problem with traditional ridge tiles is that they are bedded on sand and cement. This crumbles over time, become porous, drop out and are often found scattered down the main roof. If ridge tiles come off during high winds, this can cause significant damage or injury. There are, on average 10 deaths per year due to falling ridge tiles. Ridge tiles can be attended to in the following three ways:

Ridge lift and rebed

This involves removing all of the ridge tiles and the mortar below. Ridges are then either replaced or cleaned up and then rebedded on a full new sand and cement bed with plasticiser. New hip irons are often installed on hipped tiled roofs.

£180 per linear metre (inc VAT). 2 Month guarantee.

Dry ridge systems

In the late 1990s, there was an increase and demand for a longer lasting method of fastening ridge tiles to a main roof. Traditional sand and cement will last between 1 and 5 years and this wasn’t good enough for homeowners wishing to obtain longer guarantees. The invention came to replace sand and cement with a new flashing kit and often fiberglass trays in order to add great length of service, durability and flexibility during high winds and storms. Findley Roofing’s new dry ridge systems have been tested in 200mph wind tunnels and are extremely robust.

£230 per linear metre (inc VAT ). 10 year guarantee.