Page 9 - noopli Brochure 3R

P. 9

Product

placement.

AL

AL (out)

AL (in)

AL (out) Stores Inspection area Warehouse Area 1

Placement within less

AL (out)

Production area

critical and sensitive areas.

Lab

Clean

AL (in)

Corridor

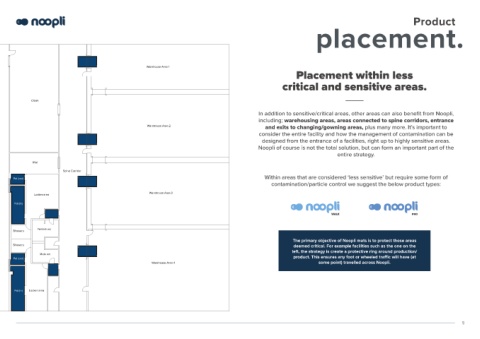

Production area In addition to sensitive/critical areas, other areas can also benefit from Noopli,

including; warehousing areas, areas connected to spine corridors, entrance

Clean in Place

AL (in) Warehouse Area 2 and exits to changing/gowning areas, plus many more. It’s important to

consider the entire facility and how the management of contamination can be

AL (out) AL (in) Corridor Lab AL designed from the entrance of a facilities, right up to highly sensitive areas.

Noopli of course is not the total solution, but can form an important part of the

entire strategy.

Prep Mal

Spine Corridor

Prep Prep Pal (out) Within areas that are considered ‘less sensitive’ but require some form of

contamination/particle control we suggest the below product types:

AL Pal (in)

Locker area Warehouse Area 3

Pal (in)

Mal (in)

AL (in) Corridor AL (out)

AL (out) Female wc

AL (in) Showers

Clean in Place

Corridor

The primary objective of Noopli mats is to protect those areas

Mal (in)

Production area Showers deemed critical. For example facilities such as the one on the

left, the strategy is create a protective ring around production/

Male wc

Pal (out) product. This ensures any foot or wheeled traffic will have (at

Mal (in) Warehouse Area 4 some point) travelled across Noopli.

Lab

Production area

Pal (in) Locker area

AL (out) Stores Stores

AL AL (out)

9