Page 72 - Australasian Paint & Panel magazine July-August 2022

P. 72

Compressor care

72

PAINT&PANEL JULY / AUGUST 2022

A WORKSHOP’S LUNGS

YOUR COMPRESSOR ACTS AS THE LUNGS OF THE WORKSHOP AND YOU CAN’T REPAIR WITHOUT IT. YET SO MANY SHOPS NEGLECT THEIR COMPRESSORS. KARL ISHERWOOD FROM ANEST IWATA/ BROADBENT TELLS YOU HOW TO AVOID COMPRESSOR DOWNTIME.

ITING THE COMPRES-

sor. In the immortal words of Patrick Swayze from Dirty Dancing: “Nobody puts baby in the corner.” However, in

S

the case of your compressor you can as long as there is enough airflow to keep it cool. Location is vital to en- sure your compressor performs as it should. Never put it near a west fac- ing wall or in an enclosed space where it will overheat. Don’t stick it out of sight behind your booths where not only is it likely to get cov- ered in dust, it will be inaccessible for servicing. Many people want to put the compressor outside to save space in the workshop. If it’s in an uncovered area then it vulnerable to dust and water. Even in a covered outside area there will still be too much moisture which can damage the electronic systems.

SIZE MATTERS. You need to undertake and air audit of what the workshop needs and then build a buffer on top of that to ensure you get a unit big enough. You also have to consider any expansion plans – a couple of extra team members using air all day could adversely affect compres- sor performance.

PIPE UP. Another common problem is contractors such as booth manufac- turers installing pipework that is too narrow. People think that air pres- sure is the critical factor but you can’t achieve good air pressure with- out air volume.

DUST IS THE ENEMY. If your compressor isn’t shielded from dust generated in the workshop the intake valves will get blocked leading to unit failure.

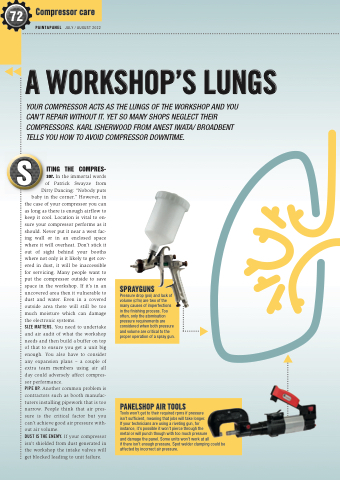

SPRAYGUNS

Pressure drop (psi) and lack of volume (cfm) are two of the many causes of imperfections in the finishing process. Too often, only the atomisation pressure requirements are considered when both pressure and volume are critical to the proper operation of a spray gun.

PANELSHOP AIR TOOLS

Tools won’t get to their required rpms if pressure

isn’t sufficient, meaning that jobs will take longer.

If your technicians are using a riveting gun, for

instance, it’s possible it won’t pierce through the

metal or will punch though with too much pressure

and damage the panel. Some units won’t work at all

if there isn’t enough pressure. Spot welder clamping could be affected by incorrect air pressure.