Page 52 - Zero is Possible - Volume 2

P. 52

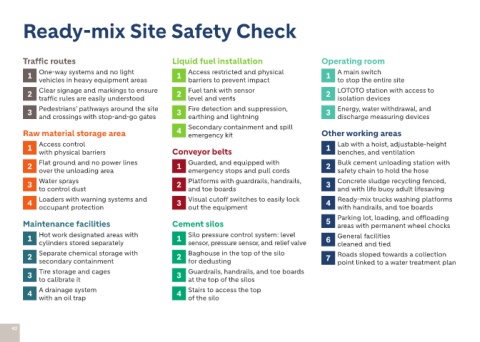

Ready-mix Site Safety Check

Traffic routes Liquid fuel installation Operating room

1 One-way systems and no light 1 Access restricted and physical 1 A main switch

vehicles in heavy equipment areas barriers to prevent impact to stop the entire site

2 Clear signage and markings to ensure 2 Fuel tank with sensor 2 LOTOTO station with access to

traffic rules are easily understood level and vents isolation devices

3 Pedestrians’ pathways around the site 3 Fire detection and suppression, 3 Energy, water withdrawal, and

and crossings with stop-and-go gates earthing and lightning discharge measuring devices

Raw material storage area 4 Secondary containment and spill Other working areas

emergency kit

1 Access control 1 Lab with a hoist, adjustable-height

with physical barriers Conveyor belts benches, and ventilation

2 Flat ground and no power lines 1 Guarded, and equipped with 2 Bulk cement unloading station with

over the unloading area emergency stops and pull cords safety chain to hold the hose

3 Water sprays 2 Platforms with guardrails, handrails, 3 Concrete sludge recycling fenced,

to control dust and toe boards and with life buoy adult lifesaving

4 Loaders with warning systems and 3 Visual cutoff switches to easily lock 4 Ready-mix trucks washing platforms

occupant protection out the equipment with handrails, and toe boards

Parking lot, loading, and offloading

Maintenance facilities Cement silos 5 areas with permanent wheel chocks

1 Hot work designated areas with 1 Silo pressure control system: level 6 General facilities

cylinders stored separately sensor, pressure sensor, and relief valve cleaned and tied

2 Separate chemical storage with 2 Baghouse in the top of the silo 7 Roads sloped towards a collection

secondary containment for dedusting point linked to a water treatment plan

Tire storage and cages Guardrails, handrails, and toe boards

3 3

to calibrate it at the top of the silos

4 A drainage system 4 Stairs to access the top

with an oil trap of the silo

42