Page 458 - Icon Ridge Hardware & Fixing Technology Catalog

P. 458

Chemical products for construction

Zinc-flake spray L228

• Highly effective thin layer of zinc

• Ideal for subsoil structures or as a stable surface

• Long-term corrosion protection with additional barrier protection due

to zinc flakes

and nano particles

• Ideal as excellent metal primer for original manufacture and repair of

damaged zinc phosphate layers

• Quick-drying, can be spot-welded and levelled over, good

functionality in conjunction with PU and MS polymer sealants, can be

over-painted using commercial 1K and 2K topcoat systems (prior

compatibility testing recommended )

• Temperature resistant up to +240°C

• Drying:

- bone-dry: approx. 15 min

- grip-dry: approx. 30 min

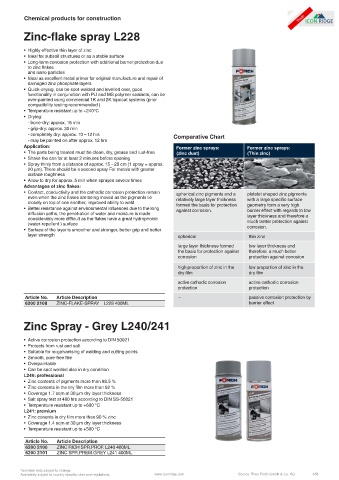

- completely dry: approx. 10 – 12 hrs Comparative Chart

- may be painted on after approx. 12 hrs

Application: Former zinc sprays: Former zinc sprays:

• The parts being treated must be clean, dry, grease and rust-free (zinc dust) (Thin zinc)

• Shake the can for at least 2 minutes before opening

• Spray thinly from a distance of approx. 15 – 20 cm (1 spray = approx.

20 µm). There should be a second spray For metals with greater

surface roughness

• Allow to dry for approx. 5 min when sprayed several times

Advantages of zinc flakes:

• Contact, conductivity and the cathodic corrosion protection remain spherical zinc pigments and a platelet shaped zinc pigments

even when the zinc flakes are being moved as the pigments lie relatively large layer thickness with a large specific surface

closely on top of one another, improved ability to weld

formed the basis for protection geometry form a very high

• Better resistance against environmental influences due to the long against corrosion. barrier effect with regards to low

diffusion paths, the penetration of water and moisture is made

layer thickness and therefore a

considerably more difficult as the flakes have a great hydrophobic

(water-repellent ) surface much better protection against

corrosion.

• Surface of the layer is smoother and stronger, better grip and better

layer strength spherical thin zinc

large layer thickness formed low layer thickness and

the basis for protection against therefore a much better

corrosion protection against corrosion

high proportion of zinc in the low proportion of zinc in the

dry film dry film

active cathodic corrosion active cathodic corrosion

protection protection

Article No. Article Description – passive corrosion protection by

6200 2108 ZINC-FLAKE-SPRAY L228 400ML barrier effect

Zinc Spray - Grey L240/241

• Active corrosion protection according to DIN 50021

• Protects from rust and salt

• Suitable for re-galvanising of welding and cutting points

• Smooth, pore-free film

• Overpaintable

• Can be spot welded also in dry condition

L240: professional

• Zinc contents of pigments more than 98.5 %

• Zinc contents in the dry film more than 92 %

• Coverage 1.7 sqm at 30 µm dry layer thickness

• Salt spray test at 480 hrs according to DIN SS-50021

• Temperature resistant up to +600 °C

L241: premium

• Zinc conents in dry film more than 90 % zinc

• Coverage 1.4 sqm at 30 µm dry layer thickness

• Temperature resistant up to +500 °C

Article No. Article Description

6200 2100 ZINC RICH SPR.PROF. L240 400ML

6200 2101 ZINC SPR.PREM.GREY L241 400ML

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 458