Page 415 - Industrial Tools Catalog (3)

P. 415

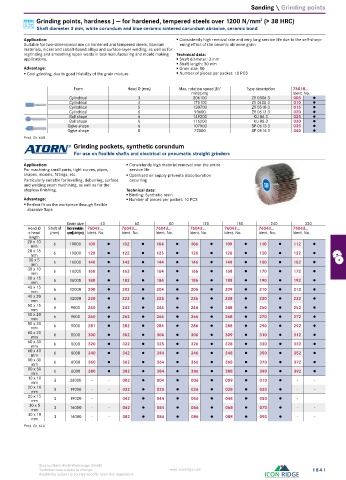

Sanding \ Grinding points

Grinding points, hardness J — for hardened, tempered steels over 1200 N/mm (> 38 HRC)

2

Shaft diameter 3 mm, white corundum and blue ceramic sintered corundum abrasive, ceramic bond

Application: Consistently high removal rate and very long service life due to the self-sharp-

Suitable for two-dimensional use on hardened and tempered steels, titanium ening effect of the ceramic abrasive grain

materials, nickel and cobalt-based alloys and surface-layer welding, as well as for

regrinding and smoothing repair welds in tool manufacturing and mould making Technical data:

applications. Shaft diameter: 3 mm

Shaft length: 30 mm

Advantage: Grain size: 80

Cool grinding, due to good friability of the grain mixture Number of pieces per packet: 10 PCS

Form Head Ø (mm) Max. rotation speed (U/ Type description 76018...

min(rpm)) Ident. No.

Cylindrical 3 206100 ZY 0306 3 005 ●

Cylindrical 4 175100 ZY 0408 3 010 ●

Cylindrical 5 130700 ZY 0510 3 015 ●

Cylindrical 6 93600 ZY 0613 3 020 ●

Ball shape 6 149200 KU 06 3 025 ●

Ball shape 8 116200 KU 08 3 030 ●

Ogive shape 6 107900 SP 0613 3 035 ●

Ogive shape 8 72800 SP 0816 3 040 ●

Prod. Gr. 6AB

Grinding pockets, synthetic corundum

For use on flexible shafts and electrical or pneumatic straight grinders

Application: Consistently high material removal over the entire

For machining small parts, tight curves, pipes, service life

shapes, models, fittings, etc. Optimised air supply prevents discolouration

Particularly suitable for levelling, deburring, surface occurring

and welding seam machining, as well as for the

stepless finishing. Technical data:

Binding: Synthetic resin

Advantage: Number of pieces per packet: 10 PCS

Perfect fit on the workpiece through flexible

abrasive flaps

Grain size 40 60 80 120 150 240 320

Head Ø Shaft Ø Recommended rotation 76043... 76043... 76043... 76043... 76043... 76043... 76043...

x head (mm) speed (U/min(rpm)) Ident. No. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No.

length

20 x 10 6 19000 100 ● 102 ● 104 ● 106 ● 109 ● 110 ● 112 ●

mm

20 x 15 6 19000 120 ● 122 ● 125 ● 126 ● 128 ● 130 ● 132 ●

mm

30 x 5 6 16000 140 ● 142 ● 144 ● 146 ● 148 ● 150 ● 152 ●

mm

30 x 10 6 16000 160 ● 162 ● 164 ● 166 ● 168 ● 170 ● 172 ●

mm

30 x 15 6 16000 180 ● 182 ● 184 ● 186 ● 188 ● 190 ● 192 ●

mm

40 x 15 6 12000 200 ● 202 ● 204 ● 206 ● 209 ● 210 ● 212 ●

mm

40 x 20 6 12000 220 ● 222 ● 225 ● 226 ● 228 ● 230 ● 232 ●

mm

50 x 15 6 9000 240 ● 242 ● 244 ● 246 ● 248 ● 250 ● 252 ●

mm

50 x 20 6 9000 260 ● 262 ● 264 ● 266 ● 268 ● 270 ● 272 ●

mm

50 x 30 6 9000 281 ● 282 ● 284 ● 286 ● 288 ● 290 ● 292 ●

mm

60 x 20 6 8000 300 ● 302 ● 304 ● 306 ● 309 ● 310 ● 312 ●

mm

60 x 30 6 8000 320 ● 322 ● 325 ● 326 ● 328 ● 330 ● 332 ●

mm

60 x 40 6 8000 340 ● 342 ● 344 ● 346 ● 348 ● 350 ● 352 ●

mm

80 x 30 6 6000 360 ● 362 ● 364 ● 366 ● 368 ● 370 ● 372 ●

mm

80 x 50 6 6000 380 ● 382 ● 384 ● 386 ● 388 ● 390 ● 392 ●

mm

10 x 10 3 38000 - - 002 ● 004 ● 006 ● 009 ● 010 ● - -

mm

20 x 10 3 19000 - - 022 ● 025 ● 026 ● 028 ● 030 ● - -

mm

20 x 15 3 19000 - - 042 ● 044 ● 046 ● 048 ● 050 ● - -

mm

30 x 5 3 16000 - - 062 ● 064 ● 066 ● 068 ● 070 ● - -

mm

30 x 10 3 16000 - - 082 ● 084 ● 086 ● 088 ● 090 ● - -

mm

Prod. Gr. 6LA

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 1841

Availability subject to country specific rules and regulations