Page 383 - Icon Ridge Maintenance & Service Catalog

P. 383

Drilling, Milling, Tapping and Threading

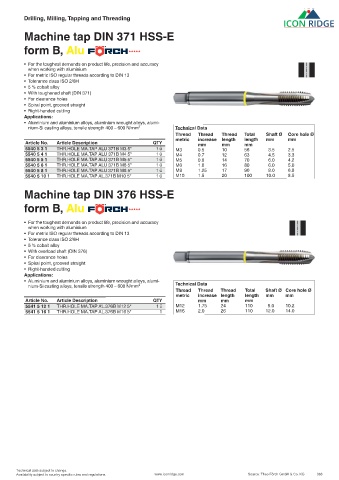

Machine tap DIN 371 HSS-E

form B, Alu

• For the toughest demands on product life, precision and accuracy

when working with aluminium

• For metric ISO regular threads according to DIN 13

• Tolerance class ISO 2/6H

• 5 % cobalt alloy

• With toughened shaft (DIN 371)

• For clearance holes

• Spiral point, grooved straight

• Right-handed cutting

Applications:

• Aluminium and aluminium alloys, aluminium wrought alloys, alumi-

nium-Si casting alloys, tensile strength 400 – 600 N/mm² Technical Data

Thread Thread Thread Total Shaft Ø Core hole Ø

metric increase length length mm mm

Article No. Article Description QTY

mm mm mm

5540 5 3 1 THR.HOLE MA.TAP ALU 371B M3 5* 1 ü M3 0.5 10 56 3.5 2.5

5540 5 4 1 THR.HOLE MA.TAP ALU 371B M4 5* 1 ü M4 0.7 12 63 4.5 3.3

5540 5 5 1 THR.HOLE MA.TAP ALU 371B M5 5* 1 ü M5 0.8 14 70 6.0 4.2

5540 5 6 1 THR.HOLE MA.TAP ALU 371B M6 5* 1 ü M6 1.0 16 80 6.0 5.0

5540 5 8 1 THR.HOLE MA.TAP ALU 371B M8 5* 1 ü M8 1.25 17 90 8.0 6.8

5540 5 10 1 THR.HOLE MA.TAP AL.371B M10 5* 1 ü M10 1.5 20 100 10.0 8.5

Machine tap DIN 376 HSS-E

form B, Alu

• For the toughest demands on product life, precision and accuracy

when working with aluminium

• For metric ISO regular threads according to DIN 13

• Tolerance class ISO 2/6H

• 5 % cobalt alloy

• With overload shaft (DIN 376)

• For clearance holes

• Spiral point, grooved straight

• Right-handed cutting

Applications:

• Aluminium and aluminium alloys, aluminium wrought alloys, alumi-

nium-Si casting alloys, tensile strength 400 – 600 N/mm² Technical Data

Thread Thread Thread Total Shaft Ø Core hole Ø

metric increase length length mm mm

Article No. Article Description QTY mm mm mm

5541 5 12 1 THR.HOLE MA.TAP AL.376B M12 5* 1 ü M12 1.75 24 110 9.0 10.2

5541 5 16 1 THR.HOLE MA.TAP AL.376B M16 5* 1 M16 2.0 26 110 12.0 14.0

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 383