Page 24 - Icon Ridge Industrial Tools Catalog

P. 24

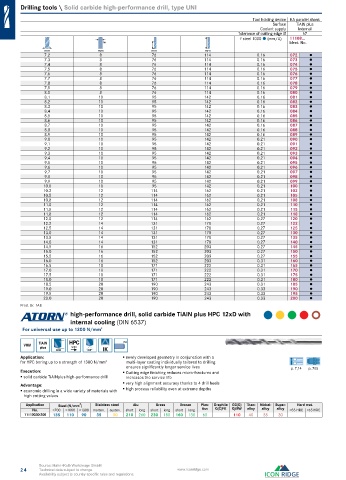

Drilling tools \ Solid carbide high-performance drill, type UNI

Tool holding device HA parallel shank

Surface TiAlN plus

Coolant supply Internal

Tolerance of cutting edge Ø h7

f steel 1000 (mm/U) 11108...

h6 Ident. No.

mm mm mm mm

7.2 8 76 114 0.16 072 ●

7.3 8 76 114 0.16 073 ●

7.4 8 76 114 0.16 074 ●

7.5 8 76 114 0.16 075 ●

7.6 8 76 114 0.16 076 ●

7.7 8 76 114 0.16 077 ●

7.8 8 76 114 0.16 078 ●

7.9 8 76 114 0.16 079 ●

8.0 8 76 114 0.16 080 ●

8.1 10 95 142 0.16 081 ●

8.2 10 95 142 0.16 082 ●

8.3 10 95 142 0.16 083 ●

8.4 10 95 142 0.16 084 ●

8.5 10 95 142 0.16 085 ●

8.6 10 95 142 0.16 086 ●

8.7 10 95 142 0.16 087 ●

8.8 10 95 142 0.16 088 ●

8.9 10 95 142 0.16 089 ●

9.0 10 95 142 0.21 090 ●

9.1 10 95 142 0.21 091 ●

9.2 10 95 142 0.21 092 ●

9.3 10 95 142 0.21 093 ●

9.4 10 95 142 0.21 094 ●

9.5 10 95 142 0.21 095 ●

9.6 10 95 142 0.21 096 ●

9.7 10 95 142 0.21 097 ●

9.8 10 95 142 0.21 098 ●

9.9 10 95 142 0.21 099 ●

10.0 10 95 142 0.21 100 ●

10.2 12 114 162 0.21 102 ●

10.5 12 114 162 0.21 105 ●

10.8 12 114 162 0.21 108 ●

11.0 12 114 162 0.21 110 ●

11.5 12 114 162 0.21 115 ●

11.8 12 114 162 0.21 118 ●

12.0 12 114 162 0.27 120 ●

12.2 14 131 178 0.27 122 ●

12.5 14 131 178 0.27 125 ●

13.0 14 131 178 0.27 130 ●

13.5 14 131 178 0.27 135 ●

14.0 14 131 178 0.27 140 ●

14.5 16 152 203 0.27 145 ●

15.0 16 152 203 0.27 150 ●

15.5 16 152 203 0.27 155 ●

16.0 16 152 203 0.31 160 ●

16.5 18 171 222 0.31 165 ●

17.0 18 171 222 0.31 170 ●

17.5 18 171 222 0.31 175 ●

18.0 18 171 222 0.31 180 ●

18.5 20 190 243 0.31 185 ●

19.0 20 190 243 0.33 190 ●

19.5 20 190 243 0.33 195 ●

20.0 20 190 243 0.33 200 ●

Prod. Gr. 1AB

high-performance drill, solid carbide TiAlN plus HPC 12xD with

internal cooling (DIN 6537)

For universal use up to 1300 N/mm 2

VHM TiAlN HPC HA

plus UNI IK

12xD 135°

Application: newly developed geometry in conjunction with a

for HPC boring up to a strength of 1300 N/mm 2 multi-layer coating individually tailored to drilling

ensures significantly longer service lives p. 7,14 p. 705

Execution: Cutting edge finishing reduces micro-fractures and

solid carbide TiAlNplus high-performance drill increases the service life

Advantage: very high alignment accuracy thanks to 4 drill heels

economic drilling in a wide variety of materials with high process reliability even at extreme depths

high cutting values

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11110030-200 135 110 90 35 30 210 260 230 180 160 130 60 110 40 35 30

Source: Hahn+Kolb Werkzeuge GmbH

24 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.