Page 360 - Icon Ridge Industrial Tools Catalog

P. 360

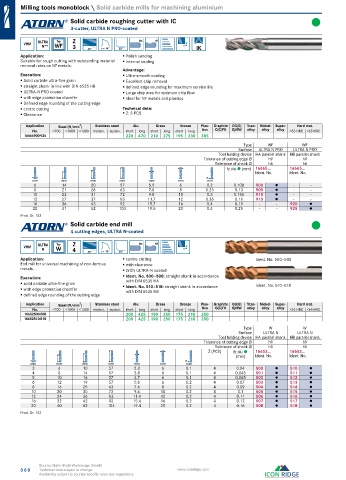

Milling tools monoblock \ Solid carbide mills for machining aluminium

Solid carbide roughing cutter with IC

3-cutter, ULTRA N PRO-coated

ULTRA Typ Z HA HB

VHM WF

N 3 γ = 14° 45° IK

Application: Polish sanding

Suitable for rough cutting with outstanding material Internal cooling

removal rates on NF metals.

Advantage:

Execution: Ultra-smooth coating

Solid carbide ultra-fine grain Excellent chip removal

straight shank in line with DIN 6535 HB defined edge rounding for maximum service life

ULTRA-N PRO coated Large chip area for optimum chip flow

with edge protection chamfer Ideal for NF metals and plastics

Defined edge rounding of the cutting edge

centre cutting Technical data:

Clearance Z: 3 PCS

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16665900-925 220 470 210 275 195 230 385

Type WF WF

Surface ULTRA N PRO ULTRA N PRO

Tool holding device HA parallel shank HB parallel shank

Tolerance of cutting edge Ø h9 h9

Tolerance of shank Ø h6 h6

fz alu (mm) 16665... 16665...

Ident. No. Ident. No.

mm mm mm mm mm mm mm

6 14 20 57 5.9 6 0.2 0.108 900 ● - -

8 21 26 63 7.8 8 0.25 0.13 905 ● - -

10 23 31 72 9.8 10 0.3 0.155 910 ● - -

12 27 37 83 11.7 12 0.35 0.18 915 ● - -

16 36 43 92 15.7 16 0.4 0.19 - - 920 ●

20 41 52 104 19.5 20 0.4 0.25 - - 925 ●

Prod. Gr. 152

Solid carbide end mill

4 cutting edges, ULTRA N-coated

VHM ULTRA Typ Z HA HB

N W 4 γ = 18° 45°

Application: centre cutting Ident. No. 500–508

End mill for universal machining of non-ferrous with clearance

metals. ZrCN ULTRA-N coated

Execution: Ident. No. 500–508: straight shank in accordance

solid carbide ultra-fine grain with DIN 6535 HA Ident. No. 510–518

with edge protection chamfer Ident. No. 510–518: straight shank in accordance

with DIN 6535 HB

defined edge rounding of the cutting edge

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16652500-508 200 425 190 250 175 210 350

16652510-518 200 425 190 250 175 210 350

Type W W

Surface ULTRA N ULTRA N

Tool holding device HA parallel shank HB parallel shank

Tolerance of cutting edge Ø h9 h9

Tolerance of shank Ø h5 h5

Z (PCS) fz alu 16652... 16652...

(mm) Ident. No. Ident. No.

mm mm mm mm mm mm mm

3 6 10 57 2.8 6 0.1 4 0.04 500 ● 510 ●

4 8 14 57 3.8 6 0.1 4 0.048 501 ● 511 ●

5 10 16 57 4.7 6 0.1 4 0.065 502 ● 512 ●

6 12 19 57 5.6 6 0.2 4 0.07 503 ● 513 ●

8 16 25 63 7.6 8 0.2 4 0.09 504 ● 514 ●

10 20 30 72 9.6 10 0.2 4 0.1 505 ● 515 ●

12 24 36 83 11.4 12 0.2 4 0.11 506 ● 516 ●

16 32 42 92 15.4 16 0.2 4 0.12 507 ● 517 ●

20 40 52 104 19.4 20 0.2 4 0.16 508 ● 518 ●

Prod. Gr. 152

Source: Hahn+Kolb Werkzeuge GmbH

360 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.