Page 367 - Icon Ridge Industrial Tools Catalog

P. 367

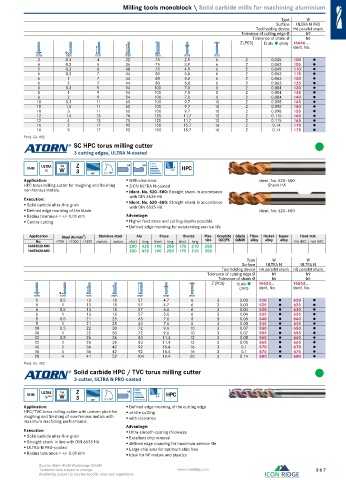

Milling tools monoblock \ Solid carbide mills for machining aluminium

Type W

Surface ULTRA N PRO

Tool holding device HA parallel shank

Tolerance of cutting edge Ø h9

Tolerance of shank Ø h6

Z (PCS) fz alu (mm) 16666...

Ident. No.

mm mm mm mm mm mm mm

3 0.3 4 32 75 2.9 6 2 0.035 100 ●

4 0.3 5 36 75 3.9 6 2 0.042 105 ●

5 0.3 6 40 75 4.9 6 2 0.049 110 ●

6 0.3 7 44 80 5.8 6 2 0.063 115 ●

6 1 7 44 80 5.8 6 2 0.063 120 ●

6 2 7 44 80 5.8 6 2 0.063 125 ●

8 0.3 9 54 100 7.8 8 2 0.084 130 ●

8 1 9 54 100 7.8 8 2 0.084 135 ●

8 2 9 54 100 7.8 8 2 0.084 140 ●

10 0.3 11 60 100 9.7 10 2 0.098 145 ●

10 1.5 11 60 100 9.7 10 2 0.098 150 ●

10 3 11 60 100 9.7 10 2 0.098 155 ●

12 1.5 13 75 120 11.7 12 2 0.115 160 ●

12 4 13 75 120 11.7 12 2 0.115 165 ●

16 2 17 92 150 15.7 16 2 0.14 170 ●

16 5 17 92 150 15.7 16 2 0.14 175 ●

Prod. Gr. 152

SC HPC torus milling cutter

3 cutting edges, ULTRA N-coated

VHM ULTRA Typ Z HA HB HPC

N W 3 γ = 18°

Application: With clearance Ident. No. 520–580

HPC torus milling cutter for roughing and finishing ZrCN ULTRA N-coated Shank HA

non-ferrous metals. Ident. No. 520–580: Straight shank in accordance

with DIN 6535 HA

Execution:

Solid carbide ultra-fine grain Ident. No. 620–680: Straight shank in accordance

with DIN 6535 HB

Defined edge rounding of the blade Ident. No. 620–680

Radius tolerance = +/- 0.01 mm Advantage:

Centre cutting Higher feed rates and cutting depths possible

Defined edge rounding for outstanding service life

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16653520-580 200 425 190 250 175 210 350

16653620-680 200 425 190 250 175 210 350

Type W W

Surface ULTRA N ULTRA N

Tool holding device HA parallel shank HB parallel shank

Tolerance of cutting edge Ø h9 h9

Tolerance of shank Ø h5 h5

Z (PCS) fz alu 16653... 16653...

(mm) Ident. No. Ident. No.

mm mm mm mm mm mm mm

5 0.5 13 18 57 4.7 6 3 0.03 520 ● 620 ●

5 1 13 18 57 4.7 6 3 0.03 525 ● 625 ●

6 0.5 13 18 57 5.6 6 3 0.04 530 ● 630 ●

6 1 13 18 57 5.6 6 3 0.04 535 ● 635 ●

8 0.5 21 25 63 7.6 8 3 0.05 540 ● 640 ●

8 1 21 25 63 7.6 8 3 0.05 545 ● 645 ●

10 0.5 22 30 72 9.6 10 3 0.07 550 ● 650 ●

10 1 22 30 72 9.6 10 3 0.07 555 ● 655 ●

12 0.5 26 36 83 11.4 12 3 0.08 560 ● 660 ●

12 1 26 36 83 11.4 12 3 0.08 565 ● 665 ●

16 2 36 42 92 15.4 16 3 0.1 570 ● 670 ●

16 4 36 42 92 15.4 16 3 0.1 575 ● 675 ●

20 4 41 52 104 19.4 20 3 0.14 580 ● 680 ●

Prod. Gr. 152

Solid carbide HPC / TVC torus milling cutter

3-cutter, ULTRA N PRO-coated

Typ

VHM ULTRA W Z HA HPC

N 3 γ = 13°

Application: Defined edge rounding of the cutting edge

HPC/TVC torus milling cutter with uneven pitch for centre cutting

roughing and finishing of non-ferrous metals with with clearance

maximum machining performance.

Advantage:

Execution: Ultra-smooth coating thickness

Solid carbide ultra-fine grain Excellent chip removal

Straight shank in line with DIN 6535 HA defined edge rounding for maximum service life

ULTRA-N PRO-coated Large chip area for optimum chip flow

Radius tolerance = +/- 0.01 mm Ideal for NF metals and plastics

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 367

Availability subject to country specific rules and regulations.