Page 391 - Icon Ridge Industrial Tools Catalog

P. 391

Milling tools monoblock \ Solid carbide barrel milling cutter

Solid carbide barrel milling cutter

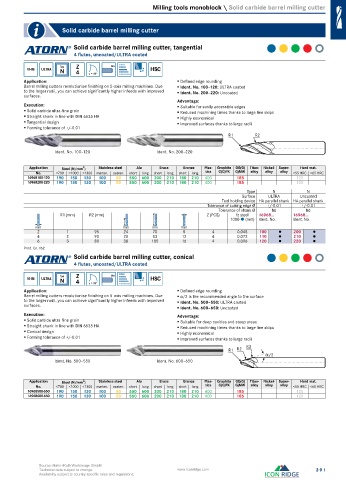

Solid carbide barrel milling cutter, tangential

4 flutes, uncoated/ULTRA coated

Typ Z HA

VHM ULTRA N 4 γ = 15° HSC

Application: Defined edge rounding

Barrel milling cutters revolutionise finishing on 5-axis milling machines. Due Ident. No. 100–120: ULTRA coated

to the larger radii, you can achieve significantly higher infeeds with improved Ident. No. 200–220: Uncoated

surfaces.

Advantage:

Execution: Suitable for easily accessible edges

Solid carbide ultra-fine grain Reduced machining times thanks to large line skips

Straight shank in line with DIN 6535 HA Highly economical

Tangential design Improved surfaces thanks to large radii

Forming tolerance of +/-0.01

R1 R2

Ident. No. 100–120 Ident. No. 200–220

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16968100-120 190 150 130 100 80 550 600 200 210 180 210 400 185 120

16968200-220 190 150 130 100 80 550 600 200 210 180 210 400 185 120

Type N N

Surface ULTRA Uncoated

Tool holding device HA parallel shank HA parallel shank

Tolerance of cutting edge Ø +/-0.01 +/-0.01

Tolerance of shank Ø h6 h6

R1 (mm) R2 (mm) Z (PCS) fz steel 16968... 16968...

1000 (mm) Ident. No. Ident. No.

mm mm mm mm

2 1 95 24 70 8 4 0.048 100 ● 200 ●

4 2 90 28 83 12 4 0.072 110 ● 210 ●

6 3 80 30 105 16 4 0.096 120 ● 220 ●

Prod. Gr. 152

Solid carbide barrel milling cutter, conical

4 flutes, uncoated/ULTRA coated

Typ Z HA

VHM ULTRA N 4 γ = 15° HSC

Application: Defined edge rounding

Barrel milling cutters revolutionise finishing on 5-axis milling machines. Due α/2 is the recommended angle to the surface

to the larger radii, you can achieve significantly higher infeeds with improved Ident. No. 500–550: ULTRA coated

surfaces.

Ident. No. 600–650: Uncoated

Execution: Advantage:

Solid carbide ultra-fine grain Suitable for deep cavities and steep areas

Straight shank in line with DIN 6535 HA Reduced machining times thanks to large line skips

Conical design Highly economical

Forming tolerance of +/-0.01 Improved surfaces thanks to large radii

R3

R1 R2

α/2

Ident. No. 500–550 Ident. No. 600–650

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16968500-550 190 150 130 100 80 550 600 200 210 180 210 400 185 120

16968600-650 190 150 130 100 80 550 600 200 210 180 210 400 185 120

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 391

Availability subject to country specific rules and regulations.