Page 410 - Icon Ridge Industrial Tools Catalog

P. 410

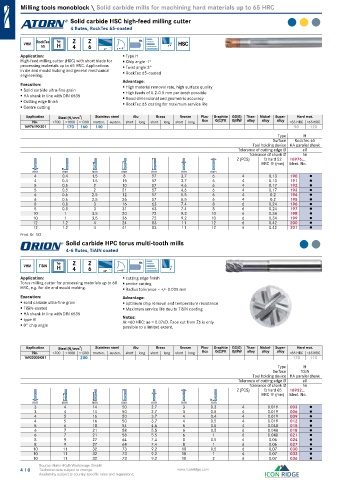

Milling tools monoblock \ Solid carbide mills for machining hard materials up to 65 HRC

Solid carbide HSC high-feed milling cutter

4 flutes, RockTec 65-coated

RockTec Typ Z Z HA

VHM H HSC

65 4 6 3° γ = -1°

Application: Type H

High-feed milling cutter (HSC) with short blade for Chip angle -1°

processing materials up to 65 HRC. Applications Twist angle 3°

in die and mould making and general mechanical RockTec 65-coated

engineering.

Advantage:

Execution: High material removal rate, high surface quality

Solid carbide ultra-fine grain High feeds of 0.2-0.5 mm per tooth possible

HA shank in line with DIN 6535 Good dimensional and geometric accuracy

Cutting edge finish RockTec 65 coating for maximum service life

Centre cutting

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16976190-201 170 160 140 90 120

Type H

Surface RockTec 65

Tool holding device HA parallel shank

Tolerance of cutting edge Ø e8

Tolerance of shank Ø h6

Z (PCS) fz hard 52 16976...

HRC (mm) Ident. No.

mm mm mm mm mm mm mm

4 0.4 1.5 8 57 3.7 6 4 0.13 190 ●

4 0.4 1.5 15 57 3.7 6 4 0.13 191 ●

5 0.5 2 10 57 4.6 6 4 0.17 192 ●

5 0.5 2 21 57 4.6 6 4 0.17 193 ●

6 0.6 2.5 12 57 5.5 6 4 0.2 194 ●

6 0.6 2.5 26 57 5.5 6 4 0.2 195 ●

8 0.8 3 16 63 7.4 8 6 0.24 196 ●

8 0.8 3 31 63 7.4 8 6 0.24 197 ●

10 1 3.5 20 72 9.2 10 6 0.34 198 ●

10 1 3.5 36 72 9.2 10 6 0.34 199 ●

12 1.2 4 24 83 11 12 6 0.42 200 ●

12 1.2 4 41 83 11 12 6 0.42 201 ●

Prod. Gr. 152

Solid carbide HPC torus multi-tooth mills

4-6 flutes, TiAlN coated

Typ Z Z HA

VHM TiSiN H 4 6 γ = 0°

Application: cutting edge finish

Torus milling cutter for processing materials up to 68 centre cutting

HRC, e.g. for die and mould making. Radius tolerance = +/- 0.005 mm

Execution: Advantage:

solid carbide ultra-fine grain optimum chip removal and temperature resistance

TiSiN-coated Maximum service life deu to TiSiN coating

HA shank in line with DIN 6535

type H Notes:

At >60 HRC: ae = 0.07xD. Face cut from Z6 is only

0° chip angle possible to a limited extent.

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16932003-051 200 170 110

Type H

Surface TiSiN

Tool holding device HA parallel shank

Tolerance of cutting edge Ø e8

Tolerance of shank Ø h6

Z (PCS) fz hard 65 16932...

HRC (mm) Ident. No.

mm mm mm mm mm mm mm

3 4 14 50 2.7 3 0.3 4 0.019 003 ●

3 4 14 50 2.7 3 0.5 4 0.019 006 ●

4 5 16 50 3.7 4 0.4 4 0.019 009 ●

4 5 16 50 3.7 4 0.5 4 0.019 012 ●

5 6 18 54 4.6 5 0.5 4 0.048 015 ●

6 7 21 58 5.5 6 0.5 6 0.048 018 ●

6 7 21 58 5.5 6 1 6 0.048 021 ●

8 9 27 64 7.4 8 0.5 6 0.06 024 ●

8 9 27 64 7.4 8 1 6 0.06 027 ●

10 11 32 73 9.2 10 0.5 6 0.07 030 ●

10 11 32 73 9.2 10 1 6 0.07 033 ●

10 11 32 73 9.2 10 2 6 0.07 036 ●

Source: Hahn+Kolb Werkzeuge GmbH

410 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.