Page 433 - Icon Ridge Industrial Tools Catalog

P. 433

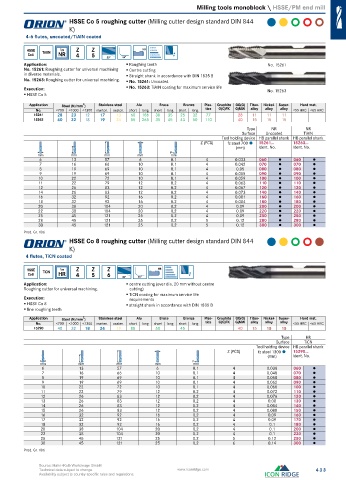

Milling tools monoblock \ HSSE/PM end mill

HSSE Co 5 roughing cutter (Milling cutter design standard DIN 844

K)

4-6 flutes, uncoated/TiAlN coated

HSSE TiAlN Typ Z Z HB

Co5 NR 4 5 45°

Application: Roughing teeth No. 15261

No. 15261: Roughing cutter for universal machining Centre cutting

in diverse materials. Straight shank in accordance with DIN 1835 B

No. 15263: Roughing cutter for universal machining. No. 15261: Uncoated

Execution: No. 15263: TiAlN coating for maximum service life No. 15263

HSSE Co 5

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

15261 28 23 12 17 13 60 186 30 35 25 32 77 28 11 11 11

15263 40 32 18 19 24 85 265 35 45 43 50 110 40 15 15 15

Type NR NR

Surface Uncoated TiAlN

Tool holding device HB parallel shank HB parallel shank

Z (PCS) fz steel 700 15261... 15263...

(mm) Ident. No. Ident. No.

mm mm mm mm mm

6 13 57 6 0.1 4 0.033 060 ● 060 ●

7 16 66 10 0.1 4 0.042 070 ● 070 ●

8 19 69 10 0.1 4 0.05 080 ● 080 ●

9 19 69 10 0.1 4 0.055 090 ● 090 ●

10 22 72 10 0.1 4 0.059 100 ● 100 ●

11 22 79 12 0.2 4 0.063 110 ● 110 ●

12 26 83 12 0.2 4 0.067 120 ● 120 ●

14 26 83 12 0.2 4 0.073 140 ● 140 ●

16 32 92 16 0.2 4 0.081 160 ● 160 ●

18 32 92 16 0.2 4 0.084 180 ● 180 ●

20 38 104 20 0.2 4 0.09 200 ● 200 ●

22 38 104 20 0.2 4 0.09 220 ● 220 ●

25 45 121 25 0.2 4 0.09 250 ● 250 ●

28 45 121 25 0.2 5 0.12 280 ● 280 ●

30 45 121 25 0.2 5 0.12 300 ● 300 ●

Prod. Gr. 106

HSSE Co 8 roughing cutter (Milling cutter design standard DIN 844

K)

4 flutes, TiCN coated

HSSE Typ Z Z Z HB

Co8 TiCN HR 4 5 6 45°

Application: centre cutting (over dia. 20 mm without centre

Roughing cutter for universal machining. cutting)

TiCN coating for maximum service life

Execution: requirements

HSSE Co 8 straight shank in accordance with DIN 1835 B

fine roughing teeth

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

15290 40 32 18 24 19 85 50 45 40 15 15 15

Type HR

Surface TiCN

Tool holding device HB parallel shank

Z (PCS) fz steel 1300 15290...

(mm) Ident. No.

mm mm mm mm mm

6 13 57 6 0.1 4 0.038 060 ●

7 16 66 10 0.1 4 0.048 070 ●

8 19 69 10 0.1 4 0.058 080 ●

9 19 69 10 0.1 4 0.062 090 ●

10 22 72 10 0.1 4 0.068 100 ●

11 22 79 12 0.2 4 0.072 110 ●

12 26 83 12 0.2 4 0.076 120 ●

13 26 83 12 0.2 4 0.08 130 ●

14 26 83 12 0.2 4 0.084 140 ●

15 26 83 12 0.2 4 0.088 150 ●

16 32 92 16 0.2 4 0.09 160 ●

17 32 92 16 0.2 4 0.09 170 ●

18 32 92 16 0.2 4 0.1 180 ●

20 38 104 20 0.2 4 0.1 200 ●

22 38 104 20 0.2 4 0.1 220 ●

25 45 121 25 0.2 5 0.12 250 ●

30 45 121 25 0.2 6 0.14 300 ●

Prod. Gr. 106

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 433

Availability subject to country specific rules and regulations.