Page 54 - Icon Ridge Industrial Tools Catalog

P. 54

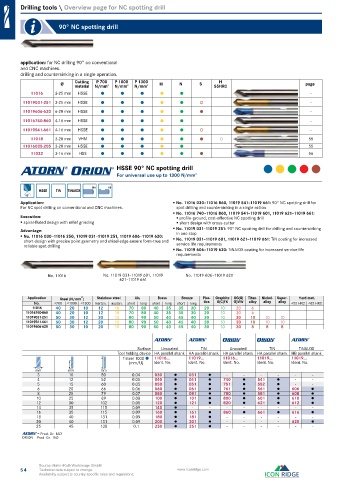

Drilling tools \ Overview page for NC spotting drill

90° NC spotting drill

application: for NC drilling 90° on conventional

and CNC machines.

drilling and countersinking in a single operation.

H

P 1300

P 700

Ø Cutting N/mm 2 P 1000 2 N/mm 2 M N S 55HRC page

N/mm

material

11016 3-25 mm HSSE -

11019031-251 3-25 mm HSSE -

11019606-620 6-20 mm HSSE -

11016740-860 4-16 mm HSSE -

11019541-661 4-16 mm HSSE -

11018 3-20 mm VHM 55

11016035-205 3-20 mm HSSE 55

11022 3-16 mm HSS 56

HSSE 90° NC spotting drill

For universal use up to 1300 N/mm 2

HA HB

HSSE TiN TiNAlOX

90°

Application: No. 11016 030–11016 860, 11019 541–11019 661: 90° NC spotting drill for

For NC spot drilling on conventional and CNC machines. spot drilling and countersinking in a single action

No. 11016 740–11016 860, 11019 541–11019 601, 11019 621–11019 661:

Execution: profile-ground, cost-effective NC spotting drill

spiral-fluted design with relief grinding short design with cross-cutter

Advantage: No. 11019 031–11019 251: 90° NC spotting drill for drilling and countersinking

No. 11016 030–11016 250, 11019 031–11019 251, 11019 606–11019 620: in one step

short design with precise point geometry and chisel edge ensure form-true and No. 11019 031–11019 601, 11019 621–11019 661: TiN coating for increased

reliable spot drilling service life requirements

No. 11019 606–11019 620: TiNAlOX coating for increased service life

requirements

No. 11016 No. 11019 031–11019 601, 11019 No. 11019 606–11019 620

621–11019 661

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11016 40 20 10 12 10 70 80 40 35 35 30 20 10 20 6

11016740-860 40 20 10 12 10 70 80 40 35 35 30 20 10 20 6

11019031-251 50 30 12 20 15 80 90 50 40 45 40 30 10 30 10 10 10

11019541-661 50 30 12 20 15 80 90 50 40 45 40 30 10 30 10 10 10

11019606-620 50 30 10 20 15 80 90 50 40 45 40 30 10 30 8 8 8

Surface Uncoated TiN Uncoated TiN TiNALOX

Tool holding device HA parallel shank HA parallel shank HA parallel shank HA parallel shank HB parallel shank

f steel 1000 11016... 11019... 11016... 11019... 11019...

(mm/U) Ident. No. Ident. No. Ident. No. Ident. No. Ident. No.

mm mm mm

3 10 50 0.04 030 ● 031 ● - - - - - -

4 12 52 0.05 040 ● 041 ● 740 ● 541 ● - -

5 15 60 0.05 050 ● 051 ● 751 ● 552 ● - -

6 20 66 0.06 060 ● 061 ● 761 ● 561 ● 606 ●

8 25 79 0.07 080 ● 081 ● 780 ● 581 ● 608 ●

10 25 89 0.08 100 ● 101 ● 800 ● 601 ● 610 ●

12 30 102 0.08 120 ● 121 ● 820 ● 621 ● 612 ●

14 35 115 0.09 140 ● - - - - - - - -

16 35 115 0.09 160 ● 161 ● 860 ● 661 ● 616 ●

18 40 131 0.09 180 ● 181 ● - - - - - -

20 40 131 0.09 200 ● 201 ● - - - - 620 ●

25 45 138 0.1 250 ● 251 ● - - - - - -

a = Prod. Gr. 1AD

ORION = Prod. Gr. 1AO

Source: Hahn+Kolb Werkzeuge GmbH

54 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.