Page 574 - Icon Ridge Industrial Tools Catalog

P. 574

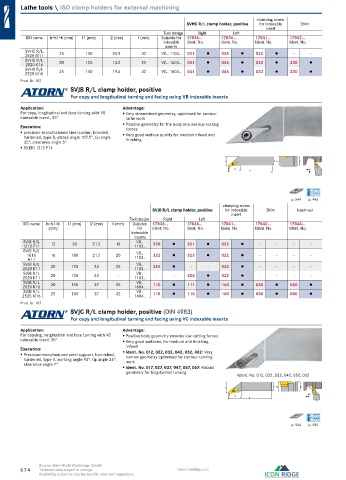

Lathe tools \ ISO clamp holders for external machining

clamping screw

SVHC R/L clamp holder, positive for indexable Shim

insert

Tool design Right Left

ISO name h=h1=b (mm) l1 (mm) l2 (mm) f (mm) Suitable for 17836... 17836... 17841... 17842...

indexable Ident. No. Ident. No. Ident. No. Ident. No.

inserts

SVHC R/L 25 150 20.9 32 VC.. 1103.. 021 ● 026 ● 022 ● - -

2525 M11

SVHC R/L 20 125 13.2 25 VC.. 1604.. 031 ● 036 ● 023 ● 230 ●

2020 K16

SVHC R/L 25 150 19.6 32 VC.. 1604.. 041 ● 046 ● 023 ● 230 ●

2525 M16

Prod. Gr. 107

SVJB R/L clamp holder, positive

For copy and longitudinal turning and facing using VB indexable inserts

Application: Advantage:

For copy, longitudinal and face turning with VB Very streamlined geometry, optimised for contour

indexable insert, 35° lathe work

Execution: Positive geometry for the body ensures low cutting

forces

precision-manufactured steel carrier, bronzed, Very good surface quality for medium infeed and

hardened, type S, attack angle 107.5°, tip angle finishing

35°, clearance angle 5°

SVJBR 1212 F11

f b h1 h

l2

l1

p. 544 p. 496

clamping screw

SVJB R/L clamp holder, positive for indexable Shim Insert nut

insert

Tool design Right Left

ISO name h=h1=b l1 (mm) l2 (mm) f (mm) Suitable 17836... 17836... 17841... 17842... 17844...

(mm) for Ident. No. Ident. No. Ident. No. Ident. No. Ident. No.

indexable

inserts

SVJB R/L 12 80 21.5 16 VB.. 320 ● 321 ● 022 ● - - - -

1212 F11 1103..

SVJB R/L VB..

1616 16 100 21.5 20 1103.. 322 ● 323 ● 022 ● - - - -

H11

SVJB R/L 20 125 23 25 VB.. 324 ● - - 022 ● - - - -

2020 K11 1103..

SVJB R/L 20 125 23 - VB.. - - 325 ● 022 ● - - - -

2020 K11 1103..

SVJB R/L 20 125 37 25 VB.. 110 ● 111 ● 160 ● 050 ● 050 ●

2020 K16 1604..

SVJB R/L 25 150 37 32 VB.. 115 ● 116 ● 160 ● 050 ● 050 ●

2525 M16 1604..

Prod. Gr. 107

SVJC R/L clamp holder, positive (DIN 4983)

For copy and longitudinal turning and facing using VC indexable inserts

Application: Advantage:

For copying, longitudinal and face turning with VC Positive body geometry ensures low cutting forces

indexable insert 35° Very good surfaces, for medium and finishing

Execution: infeed

Precision-manufactured steel support, burnished, Ident. No. 012, 022, 032, 042, 052, 062: Very

narrow geometry optimised for contour-turning

hardened, type V, working angle 93°, tip angle 35°, work

clearance angle 7°

Ident. No. 017, 027, 037, 047, 057, 067: Robust

geometry for longitudinal turning

Ident. No. 012, 022, 032, 042, 052, 062

b h1 h

f

l2

l1

p. 546 p. 496

Source: Hahn+Kolb Werkzeuge GmbH

574 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.