Page 594 - Icon Ridge Industrial Tools Catalog

P. 594

Lathe tools \ ISO clamp holder for internal machining

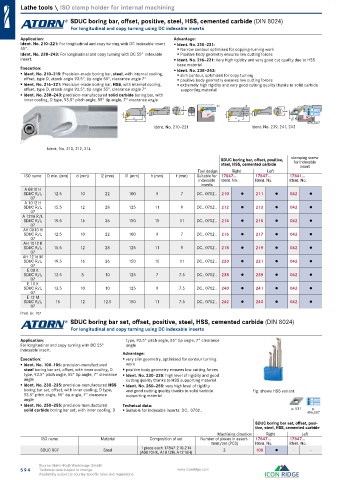

SDUC boring bar, offset, positive, steel, HSS, cemented carbide (DIN 8024)

For longitudinal and copy turning using DC indexable inserts

Application: Advantage:

Ident. No. 210–221: For longitudinal and copy turning with DC indexable insert Ident. No. 210–221:

55°. Narrow contour optimised for copying-turning work

Ident. No. 238–243: For longitudinal and copy turning with DC 55° indexable Positive body geometry ensures low cutting forces

insert. Ident. No. 216–221: Very high rigidity and very good cut quality due to HSS

base material

Execution: Ident. No. 238–243:

Ident. No. 210–215: Precision-made boring bar, steel, with internal cooling, slim contour, optimised for copy turning

offset, type D, attack angle 93.5°, tip angle 55°, clearance angle 7° positive body geometry ensures low cutting forces

Ident. No. 216–221: Precision-made boring bar, HSS, with internal cooling, extremely high rigidity and very good cutting quality thanks to solid carbide

offset, type D, attack angle 93.5°, tip angle 55°, clearance angle 7° supporting material

Ident. No. 238–243: precision-manufactured solid carbide boring bar, with

inner cooling, D type, 93.5° pitch angle, 55° tip angle, 7° clearance angle

d d

ØDmin. ØDmin.

h1 h1

f h f1

H

l2 l1 p. 531 p.

l1 l2 496,587

Ident. No. 210–221 Ident. No. 239, 241, 243

Ident. No. 210, 212, 214

SDUC boring bar, offset, positive, clamping screw

steel, HSS, cemented carbide for indexable

insert

Tool design Right Left

ISO name D min. (mm) d (mm) l2 (mm) l1 (mm) h (mm) f (mm) Suitable for 17847... 17847... 17841...

indexable Ident. No. Ident. No. Ident. No.

inserts

A 0810 H

SDUC R/L 12.5 10 22 100 9 7 DC.. 0702.. 210 ● 211 ● 042 ●

07

A 1012 H

SDUC R/L 15.5 12 28 125 11 9 DC.. 0702.. 212 ● 213 ● 042 ●

07

A 1216 R/L

SDUC R/L 19.5 16 36 150 15 11 DC.. 0702.. 214 ● 215 ● 042 ●

07

AH 0810 H

SDUC R/L 12.5 10 22 100 9 7 DC.. 0702.. 216 ● 217 ● 042 ●

07

AH 1012 K

SDUC R/L 15.5 12 28 125 11 9 DC.. 0702.. 218 ● 219 ● 042 ●

07

AH 1216 M

SDUC R/L 19.5 16 36 150 15 11 DC.. 0702.. 220 ● 221 ● 042 ●

07

E 08 K

SDUC R/L 13.5 8 10 125 7 7.5 DC.. 0702.. 238 ● 239 ● 042 ●

07

E 10 K

SDUC R/L 13.5 10 10 125 9 7.5 DC.. 0702.. 240 ● 241 ● 042 ●

07

E 12 M

SDUC R/L 15 12 12.5 150 11 7.5 DC.. 0702.. 242 ● 243 ● 042 ●

07

Prod. Gr. 107

SDUC boring bar set, offset, positive, steel, HSS, cemented carbide (DIN 8024)

For longitudinal and copy turning using DC indexable inserts

Application: type, 93.5° pitch angle, 55° tip angle, 7° clearance

For longitudinal and copy turning with DC 55° angle

indexable insert.

Advantage:

Execution: very slim geometry, optimised for contour turning

Ident. No. 100–105: precision-manufactured work

steel boring bar set, offset, with inner cooling, D positive body geometry ensures low cutting forces

type, 93.5° pitch angle, 55° tip angle, 7° clearance Ident. No. 230–235: high level of rigidity and good

angle cutting quality thanks to HSS supporting material

Ident. No. 230–235: precision-manufactured HSS Ident. No. 250–255: very high level of rigidity

boring bar set, offset, with inner cooling, D type, and good cutting quality thanks to solid carbide Fig. shows HSS variant

93.5° pitch angle, 55° tip angle, 7° clearance supporting material

angle

Ident. No. 250–255: precision-manufactured Technical data:

p.

solid carbide boring bar set, with inner cooling, D Suitable for indexable inserts: DC.. 0702.. p. 531 496,587

SDUC boring bar set, offset, posi-

tive, steel, HSS, cemented carbide

Machining direction Right Left

ISO name Material Composition of set Number of pieces in assort- 17847... 17847...

ment/set (PCS) Ident. No. Ident. No.

1 piece each 17847 210-214

SDUC R07 Steel (A0810HK, A1012H, A1216H) 3 100 ● - -

Source: Hahn+Kolb Werkzeuge GmbH

594 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.