Page 614 - Icon Ridge Industrial Tools Catalog

P. 614

Lathe tools \ Miniature boring range, front end D=8-13 mm

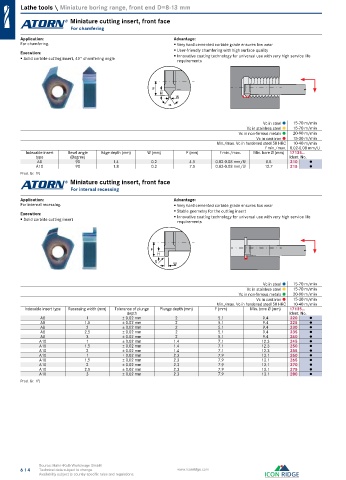

Miniature cutting insert, front face

For chamfering

Application: Advantage:

For chamfering. Very hard cemented carbide grade ensures low wear

User-friendly chamfering with high surface quality

Execution:

Solid carbide cutting insert, 45° chamfering angle Innovative coating technology for universal use with very high service life

requirements

F

H

W

Vc in steel 15-70 m/min

Vc in stainless steel 15-70 m/min

Vc in non-ferrous metals 20-90 m/min

Vc in cast iron 15-30 m/min

Min./max. Vc in hardened steel 50 HRC 10-40 m/min

f min./max. 0.02-0.08 mm/U

Indexable insert Bevel angle Edge depth (mm) W (mm) F (mm) f min./max. Min. bore Ø (mm) 17135...

type (Degree) Ident. No.

A8 90 1.4 0.2 4.5 0.02-0.08 mm/U 8.8 210 ●

A10 90 1.8 0.2 7.5 0.02-0.08 mm/U 12.7 215 ●

Prod. Gr. 1FJ

Miniature cutting insert, front face

For internal recessing

Application: Advantage:

For internal recessing. Very hard cemented carbide grade ensures low wear

Stable geometry for the cutting insert

Execution:

Solid carbide cutting insert Innovative coating technology for universal use with very high service life

requirements

F

H

R W

Vc in steel 15-70 m/min

Vc in stainless steel 15-70 m/min

Vc in non-ferrous metals 20-90 m/min

Vc in cast iron 15-30 m/min

Min./max. Vc in hardened steel 50 HRC 10-40 m/min

Indexable insert type Recessing width (mm) Tolerance of plunge Plunge depth (mm) F (mm) Min. bore Ø (mm) 17135...

depth Ident. No.

A8 1 ± 0.02 mm 2 5.1 9.4 220 ●

A8 1.5 ± 0.02 mm 2 5.1 9.4 225 ●

A8 2 ± 0.02 mm 2 5.1 9.4 230 ●

A8 2.5 ± 0.02 mm 2 5.1 9.4 235 ●

A8 3 ± 0.02 mm 2 5.1 9.4 240 ●

A10 1 ± 0.02 mm 1.4 7.1 12.3 245 ●

A10 1.5 ± 0.02 mm 1.4 7.1 12.3 250 ●

A10 2 ± 0.02 mm 1.4 7.1 12.3 255 ●

A10 1 ± 0.02 mm 2.3 7.9 13.1 260 ●

A10 1.5 ± 0.02 mm 2.3 7.9 13.1 265 ●

A10 2 ± 0.02 mm 2.3 7.9 13.1 270 ●

A10 2.5 ± 0.02 mm 2.3 7.9 13.1 275 ●

A10 3 ± 0.02 mm 2.3 7.9 13.1 280 ●

Prod. Gr. 1FJ

Source: Hahn+Kolb Werkzeuge GmbH

614 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.