Page 658 - Icon Ridge Industrial Tools Catalog

P. 658

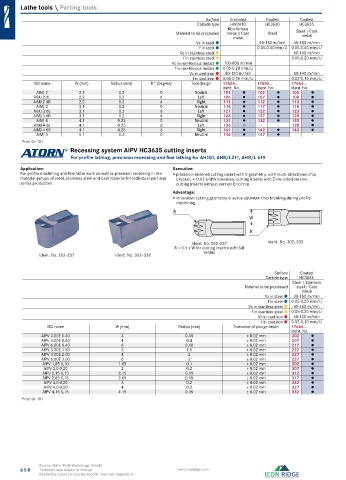

Lathe tools \ Parting tools

Surface Uncoated Coated Coated

Carbide type HW3410 HC3630 HC3635

Non-ferrous

Material to be processed metal | Cast Steel Steel | Cast

metal

metal

Vc in steel 40-150 m/min 45-180 m/min

f in steel 0.05-0.40 mm/U 0.05-0.40 mm/U

Vc in stainless steel 60-160 m/min

f in stainless steel 0.05-0.20 mm/U

Vc in non-ferrous metals 100-600 m/min

f in non-ferrous metals 0.05-0.20 mm/U

Vc in cast iron 80-120 m/min 80-140 m/min

f in cast iron 0.05-0.15 mm/U 0.02-0.15 mm/U

ISO name W (mm) Radius (mm) K° (Degree) Tool design 17666... 17666... 17666...

Ident. No. Ident. No. Ident. No.

AIMJ 2 2.2 0.2 0 Neutral 101 ● 102 ● 103 ●

AIMJ 2 6L 2.2 0.2 6 Left 106 ● 107 ● 108 ●

AIMJ 2 6R 2.2 0.2 6 Right 111 ● 112 ● 113 ●

AIMJ 3 3.1 0.2 0 Neutral 116 ● 117 ● 118 ●

AIMJ 3 6L 3.1 0.2 6 Left 121 ● 122 ● 123 ●

AIMJ 3 6R 3.1 0.2 6 Right 126 ● 127 ● 128 ●

AIMJ 4 4.1 0.25 0 Neutral 131 ● 132 ● 133 ●

AIMJ 4 6L 4.1 0.25 6 Left 136 ○ - - 138 ●

AIMJ 4 6R 4.1 0.25 6 Right 141 ● 142 ● 143 ●

AIMJ 5 5.1 0.3 0 Neutral 146 ● 147 ● - -

Prod. Gr. 181

Recessing system AIPV HC3635 cutting inserts

For profile lathing, precision recessing and fine lathing for AH101, AHR/L211, AHR/L 619

Application: Execution:

For profile machining and fine lathe work as well as precision recessing in the precision-sintered cutting insert with V geometry, with multi-directional chip

material groups of steel, stainless steel and cast material for individual part and breaker, +-0.02 width tolerance, cutting inserts with E=rounded version,

series production. cutting inserts without version E=circlip

Advantage:

innovative cutting geometry ensures optimum chip breaking during profile

machining

R

W

R

Ident. No. 202–237 Ident. No. 302–332

R = 0.5 x W for cutting inserts with full

Ident. No. 202–237 Ident. No. 302–332 radius

Surface Coated

Carbide type HC3635

Steel | Stainless

Material to be processed steel | Cast

metal

Vc in steel 30-160 m/min

f in steel 0.05-0.25 mm/U

Vc in stainless steel 40-140 m/min

f in stainless steel 0.05-0.20 mm/U

Vc in cast iron 60-120 m/min

f in cast iron 0.02-0.10 mm/U

ISO name W (mm) Radius (mm) Tolerance of plunge depth 17666...

Ident. No.

AIPV 3.00E 0.40 3 0.40 ± 0.02 mm 202 ●

AIPV 4.00E 0.40 4 0.4 ± 0.02 mm 207 ●

AIPV 6.00E 0.40 6 0.40 ± 0.02 mm 217 ●

AIPV 3.00E 1.50 3 1.5 ± 0.02 mm 222 ●

AIPV 4.00E 2.00 4 2 ± 0.02 mm 227 ●

AIPV 6.00E 3.00 6 3 ± 0.02 mm 237 ●

AIPV 1,85 0,10 1.85 0.1 ± 0.02 mm 302 ●

AIPV 2,0 0,20 2 0.2 ± 0.02 mm 307 ●

AIPV 2,15 0,15 2.15 0.15 ± 0.02 mm 312 ●

AIPV 2,65 0,15 2.65 0.15 ± 0.02 mm 317 ●

AIPV 3,0 0,20 3 0.2 ± 0.02 mm 322 ●

AIPV 4,0 0,20 4 0.2 ± 0.02 mm 327 ●

AIPV 4,15 0,15 4.15 0.15 ± 0.02 mm 332 ●

Prod. Gr. 181

Source: Hahn+Kolb Werkzeuge GmbH

658 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.