Page 666 - Icon Ridge Industrial Tools Catalog

P. 666

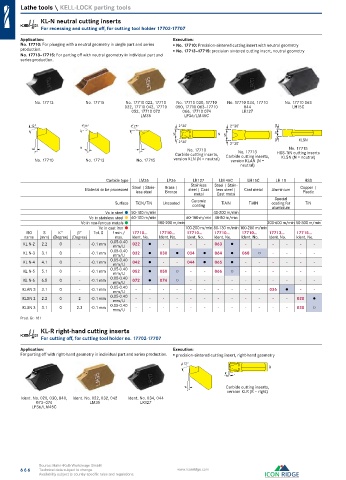

Lathe tools \ KELL-LOCK parting tools

KL-N neutral cutting inserts

For recessing and cutting off, for cutting tool holder 17702-17707

Application: Execution:

No. 17710: For plunging with a neutral geometry in single part and series No. 17710: Precision-sintered cutting insert with neutral geometry

production. No. 17713–17715: precision-sintered cutting insert, neutral geometry

No. 17713–17715: For parting off with neutral geometry in individual part and

series production.

No. 17713 No. 17715 No. 17710 022, 17710 No. 17710 030, 17710 No. 17710 034, 17710 No. 17710 068

032, 17710 042, 17710 050, 17710 063–17710 044 LH15C

052, 17710 072 066, 17710 074 LR127

LM35 LP36/LM45C

12° 26° 25° 2°30’ 2°30’

S N S S

2°30’ KLSN

2°30’

N No. 17715

No. 17710

No. 17713

7° 7° 7° Carbide cutting inserts, Carbide cutting inserts, HSS-TiN cutting inserts

No. 17710 No. 17713 No. 17715 version KLN (N = neutral) version KLAN (N = KLSN (N = neutral)

neutral)

Carbide type LM35 LP36 LR127 LM 45C LH15C LH 10 HSS

Stainless

Material to be processed Steel | Stain- Brass | steel | Cast Steel | Stain- Cast metal Aluminium Copper |

less steel |

Bronze

less steel

Plastic

metal

Cast metal

Special

Surface TiCN/TiN Uncoated Ceramic TiAlN TiAlN coating for TiN

coating

Vc in steel 50-180 m/min 40-200 m/min aluminium

Vc in stainless steel 60-100 m/min 60-100 m/min 40-80 m/min

Vc in non-ferrous metals 100-200 m/min 200-600 m/min 50-300 m/min

Vc in cast iron 100-200 m/min 80-130 m/min 100-200 m/min

ISO S K° β° Tol. S f min./ 17710... 17710... 17710... 17710... 17710... 17713... 17715...

name (mm) (Degree) (Degree) max. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No.

KL N-2 2.2 0 - -0.1 mm 0.05-0.40 022 ● - - - - 063 ● - - - - - -

mm/U

KL N-3 3.1 0 - -0.1 mm 0.05-0.40 032 ● 030 ● 034 ● 064 ● 068 ○ - - - -

mm/U

KL N-4 4.1 0 - -0.1 mm 0.05-0.40 042 ● - - 044 ● 065 ● - - - - - -

mm/U

KL N-5 5.1 0 - -0.1 mm 0.05-0.40 052 ● 050 ○ - - 066 ○ - - - - - -

mm/U

KL N-6 6.5 0 - -0.1 mm 0.05-0.40 072 ● 074 ○ - - - - - - - - - -

mm/U

KLAN 3 3.1 0 - -0.1 mm 0.05-0.40 - - - - - - - - - - 036 ● - -

mm/U

KLSN 2 2.2 0 2 -0.1 mm 0.05-0.40 - - - - - - - - - - - - 020 ●

mm/U

KLSN 3 3.1 0 2.3 -0.1 mm 0.05-0.40 - - - - - - - - - - - - 030 ○

mm/U

Prod. Gr. 181

KL-R right-hand cutting inserts

For cutting off, for cutting tool holder no. 17702-17707

Application: Execution:

For parting off with right-hand geometry in individual part and series production. precision-sintered cutting insert, right-hand geometry

12°

R

K

Carbide cutting inserts,

7° version KLR (R = right)

Ident. No. 020, 030, 040, Ident. No. 022, 032, 042 Ident. No. 034, 044

073–074 LM35 LR127

LP36/LM45C

Source: Hahn+Kolb Werkzeuge GmbH

666 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.