Page 155 - Industrial Tools Catalog (1)

P. 155

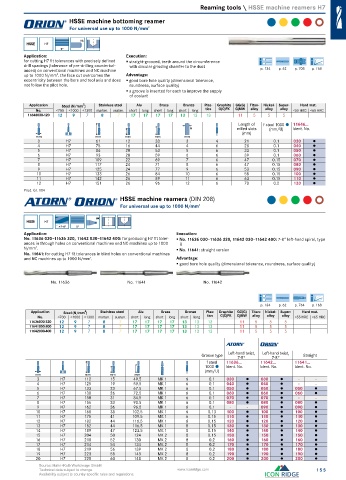

Reaming tools \ HSSE machine reamers H7

HSSE machine bottoming reamer

For universal use up to 1000 N/mm 2

HA

HSSE H7

0°

Application: Execution:

for cutting H7 fit tolerances with precisely defined straight-grooved, teeth around the circumference

drill spacings (tolerance of pre-drilling counterbal- with circular grinding chamfer to the duct

anced) on conventional machines and NC machine p. 134 p. 62 p. 703 p. 168

up to 1000 N/mm . the face cut overcomes the Advantage:

2

eccentricity between the bore and tool axis and does good bore hole quality (dimensional tolerance,

not follow the pilot hole. roundness, surface quality)

a groove is inserted for each to improve the supply

of coolant

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11646030-120 12 9 7 8 7 17 17 17 17 13 13 13 11 5 5 5

Length of f steel 1000 11646...

h6 milled slots (mm/U) Ident. No.

(mm)

mm mm mm mm mm

3 H7 61 12 33 3 4 21 0.1 030 ●

4 H7 75 16 44 4 6 28 0.1 040 ●

5 H7 86 20 53 5 6 33 0.1 050 ●

6 H7 93 20 59 6 6 39 0.1 060 ●

7 H7 109 22 69 7 6 47 0.15 070 ●

8 H7 117 24 71 8 6 47 0.15 080 ●

9 H7 125 24 77 9 6 53 0.15 090 ●

10 H7 133 26 84 10 6 58 0.15 100 ●

11 H7 142 26 89 11 6 63 0.15 110 ●

12 H7 151 26 96 12 6 70 0.2 120 ●

Prod. Gr. 104

HSSE machine reamers (DIN 208)

For universal use up to 1000 N/mm 2

MK

HSSE H7

7–8° 0°

Application: Execution:

No. 11636 030–11636 320, 11642 030–11642 400: for producing H7 fit toler- No. 11636 030–11636 320, 11642 030–11642 400: 7-8° left-hand spiral, type

ances in through holes on conventional machines and NC machines up to 1000 B

N/mm . 2 No. 11641: straight version

No. 11641: for cutting H7 fit tolerances in blind holes on conventional machines

and NC machines up to 1000 N/mm . 2 Advantage:

good bore hole quality (dimensional tolerance, roundness, surface quality)

No. 11636 No. 11641 No. 11642

p. 134 p. 62 p. 764 p. 168

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11636030-320 12 9 7 8 7 17 17 17 17 13 13 13 11 5 5 5

11641050-300 12 9 7 8 7 17 17 17 17 13 13 13 11 5 5 5

11642030-400 12 9 7 8 7 17 17 17 17 13 13 13 11 5 5 5

Groove type Left-hand twist, Left-hand twist, Straight

7-8°

7-8°

f steel 11636... 11642... 11641...

1000 Ident. No. Ident. No. Ident. No.

(mm/U)

mm mm mm mm

3 H7 112 15 49.5 MK 1 6 0.1 030 ● 030 ● - -

4 H7 125 19 59.5 MK 1 6 0.1 040 ● 040 ● - -

5 H7 133 23 67.5 MK 1 6 0.1 050 ● 050 ● 050 ●

6 H7 138 26 72.5 MK 1 6 0.1 060 ● 060 ● 060 ●

7 H7 150 31 84.5 MK 1 6 0.1 070 ● 070 ● - -

8 H7 156 33 90.5 MK 1 6 0.1 080 ● 080 ● 080 ●

9 H7 162 36 96.5 MK 1 6 0.1 - - 090 ● 090 ●

10 H7 168 38 102.5 MK 1 6 0.13 100 ● 100 ● 100 ●

11 H7 175 41 109.5 MK 1 6 0.15 110 ● 110 ● 110 ●

12 H7 182 44 116.5 MK 1 6 0.15 120 ● 120 ● 120 ●

13 H7 182 44 116.5 MK 1 8 0.15 130 ● 130 ● 130 ●

14 H7 189 47 123.5 MK 1 8 0.15 140 ● 140 ● 140 ●

15 H7 204 50 124 MK 2 8 0.15 150 ● 150 ● 150 ●

16 H7 210 52 130 MK 2 8 0.2 160 ● 160 ● 160 ●

17 H7 214 54 134 MK 2 8 0.2 170 ● 170 ● 170 ●

18 H7 219 56 139 MK 2 8 0.2 180 ● 180 ● 180 ●

19 H7 223 58 143 MK 2 8 0.2 190 ● 190 ● 190 ●

20 H7 228 60 148 MK 2 8 0.2 200 ● 200 ● 200 ●

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 155

Availability subject to country specific rules and regulations.