Page 240 - Industrial Tools Catalog (1)

P. 240

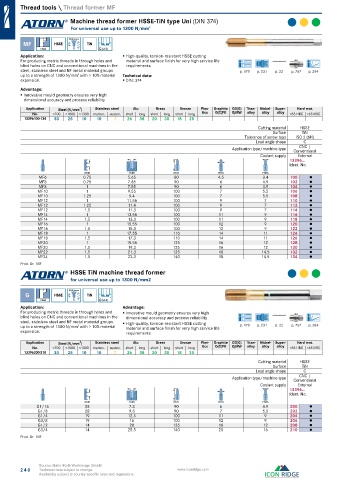

Thread tools \ Thread former MF

Machine thread former HSSE-TiN type Uni (DIN 374)

For universal use up to 1300 N/mm 2

CNC/conv.

MF HSSE TiN

3xd C (2-3)

Application: High-quality, torsion-resistant HSSE cutting

For producing metric threads in through holes and material and surface finish for very high service life

blind holes on CNC and conventional machines in the requirements

steel, stainless steel and NF metal material groups p. 170 p. 231 p. 22 p. 757 p. 284

up to a strength of 1300 N/mm with > 10% material Technical data:

2

expansion. DIN: 374

Advantage:

Innovative mould geometry ensures very high

dimensional accuracy and process reliability

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13396100-134 30 25 10 10 7 26 38 20 30 18 25

Cutting material HSSE

Surface TiN

Tolerance of screw taps ISO 2 (6H)

Lead angle shape C

CNC |

Application type/machine type Conventional

Coolant supply External

13396...

Ident. No.

mm mm mm mm mm

MF6 0.75 5.65 80 4.5 3.4 100 ●

MF8 0.75 7.65 90 6 4.9 102 ●

MF8 1 7.55 90 6 4.9 104 ●

MF10 1 9.55 100 7 5.5 106 ●

MF10 1.25 9.4 100 7 5.5 108 ●

MF12 1 11.55 100 9 7 110 ●

MF12 1.25 11.4 100 9 7 112 ●

MF12 1.5 11.3 100 9 7 114 ●

MF14 1 13.55 100 11 9 116 ●

MF14 1.5 13.3 100 11 9 118 ●

MF16 1 15.55 100 12 9 120 ●

MF16 1.5 15.3 100 12 9 122 ●

MF18 1 17.55 110 14 11 124 ●

MF18 1.5 17.3 110 14 11 126 ●

MF20 1 19.55 125 16 12 128 ●

MF20 1.5 19.3 125 16 12 130 ●

MF22 1.5 21.3 125 18 14.5 132 ●

MF24 1.5 23.3 140 18 14.5 134 ●

Prod. Gr. 1KF

HSSE TiN machine thread former

for universal use up to 1300 N/mm2

CNC/conv.

G HSSE TiN

3xd C (2-3)

Application: Advantage:

For producing metric threads in through holes and Innovative mould geometry ensures very high

blind holes on CNC and conventional machines in the dimensional accuracy and process reliability

steel, stainless steel and NF metal material groups High-quality, torsion-resistant HSSE cutting

up to a strength of 1300 N/mm with > 10% material material and surface finish for very high service life p. 170 p. 231 p. 22 p. 757 p. 284

2

expansion. requirements

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13396200-210 30 25 10 10 7 26 38 20 30 18 25

Cutting material HSSE

Surface TiN

Lead angle shape C

CNC |

Application type/machine type Conventional

Coolant supply External

13396...

Ident. No.

mm mm mm mm mm

G1/16 28 7.3 90 6 4.9 200 ●

G1/8 28 9.3 90 7 5.5 202 ●

G1/4 19 12.5 100 11 9 204 ●

G3/8 19 16 100 12 9 206 ●

G1/2 14 20 125 16 12 208 ●

G3/4 14 25.5 140 20 16 210 ●

Prod. Gr. 1KF

Source: Hahn+Kolb Werkzeuge GmbH

240 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.