Page 265 - Industrial Tools Catalog (1)

P. 265

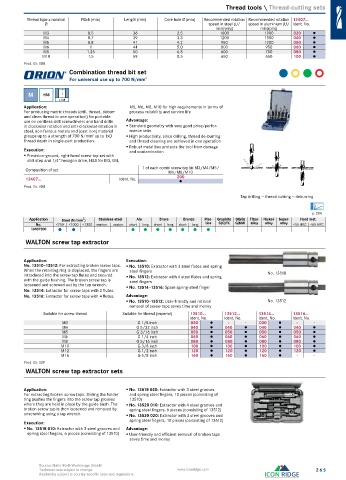

Thread tools \ Thread-cutting sets

Thread type x nominal Pitch (mm) Length (mm) Core hole Ø (mm) Recommended rotation Recommended rotation 13407...

Ø speed in steel (U/ speed in aluminium (U/ Ident. No.

min(rpm)) min(rpm))

M3 0.5 36 2.5 1600 1900 030 ●

M4 0.7 39 3.3 1200 1500 040 ●

M5 0.8 41 4.2 950 1200 050 ●

M6 1 44 5.0 800 950 060 ●

M8 1.25 50 6.8 600 700 080 ●

M10 1.5 59 8.5 450 550 100 ●

Prod. Gr. 1DB

Combination thread bit set

For universal use up to 700 N/mm 2

M HSS

1xd

Application: M5, M6, M8, M10 for high requirements in terms of

For producing metric threads (drill, thread, deburr process reliability and service life

and clean thread in one operation!) for portable

use on cordless drill screwdrivers and hand drills Advantage:

in clockwise rotation and anti-clockwise rotation in Standard geometry with very good price/perfor-

steel, non-ferrous metals and (cast iron) material mance ratio

groups up to a strength of 700 N/mm up to 1xD High productivity, since drilling, thread de-burring

2

thread depth in single-part production. and thread cleaning are achieved in one operation

Robust metal box protects the tool from damage

Execution: and contamination

Precision-ground, right-hand screw tap set with

drill step and 1/4“ hexagon drive, HSS for M3, M4,

Composition of set 1 of each combi screw tap bit M3/M4/M5/

M6/M8/M10

13407... Ident. No. 200

●

Prod. Gr. 1DB

Tap drilling — thread cutting — deburring

p. 284

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13407200

WALTON screw tap extractor

Application: Execution:

No. 13510–13512: For extracting broken screw taps. No. 13510: Extractor with 3 steel flutes and spring

When the retaining ring is displaced, the fingers are steel fingers No. 13510

introduced into the screw tap flutes and secured No. 13512: Extractor with 4 steel flutes and spring

with the guide bushing. The broken screw tap is steel fingers

loosened and screwed out by the tap wrench. No. 13514–13516: Spare spring-steel finger

No. 13514: Extractor for screw taps with 3 flutes.

No. 13516: Extractor for screw taps with 4 flutes. Advantage:

No. 13510–13512: User-friendly and rational No. 13512

removal of screw taps saves time and money

Suitable for screw thread Suitable for thread (imperial) 13510... 13512... 13514... 13516...

Ident. No. Ident. No. Ident. No. Ident. No.

M3 G 1/8 inch 030 ● - - 030 ● - -

M4 G 5/32 inch 040 ● 040 ● 040 ● 040 ●

M5 G 3/16 inch 050 ● 050 ● 050 ● 050 ●

M6 G 1/4 inch 060 ● 060 ● 060 ● 060 ●

M8 G 5/16 inch 080 ● 080 ● 080 ● 080 ●

M10 G 3/8 inch 100 ● 100 ● 100 ● 100 ●

M12 G 1/2 inch 120 ● 120 ● 120 ● 120 ●

M16 G 5/8 inch 160 ● 160 ● 160 ● - -

Prod. Gr. 139

WALTON screw tap extractor sets

Application: No. 13518 020: Extractor with 3 steel grooves

For extracting broken screw taps. Sliding the holder and spring steel fingers, 10 pieces (consisting of

ring pushes the fingers into the screw tap grooves 13510)

where they are held in place by the guide bush. The No. 13520 010: Extractor with 4 steel grooves and

broken screw tap is then loosened and removed by spring steel fingers, 6 pieces (consisting of 13512)

unscrewing using a tap wrench. No. 13520 020: Extractor with 3 steel grooves and

Execution: spring steel fingers, 10 pieces (consisting of 13512)

No. 13518 010: Extractor with 3 steel grooves and Advantage:

spring steel fingers, 6 pieces (consisting of 13510) User-friendly and efficient removal of broken taps

saves time and money

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 265

Availability subject to country specific rules and regulations.