Page 338 - Industrial Tools Catalog (1)

P. 338

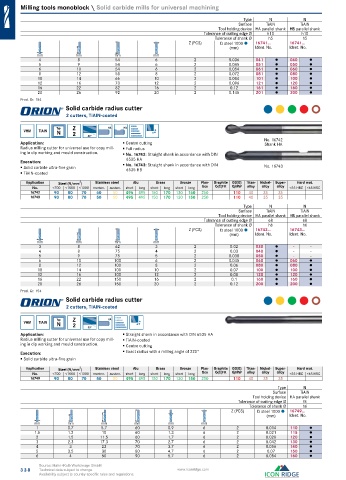

Milling tools monoblock \ Solid carbide mills for universal machining

Type N N

Surface TiAlN TiAlN

Tool holding device HA parallel shank HB parallel shank

Tolerance of cutting edge Ø h10 h10

Tolerance of shank Ø h5 h5

Z (PCS) fz steel 1000 16741... 16741...

(mm) Ident. No. Ident. No.

mm mm mm mm

4 8 54 6 2 0.036 041 ● 040 ●

5 9 54 6 2 0.045 051 ● 050 ●

6 10 54 6 2 0.054 061 ● 060 ●

8 12 58 8 2 0.072 081 ● 080 ●

10 14 66 10 2 0.084 101 ● 100 ●

12 16 73 12 2 0.096 121 ● 120 ●

16 22 82 16 2 0.12 161 ● 160 ●

20 26 92 20 2 0.145 201 ● 200 ●

Prod. Gr. 154

Solid carbide radius cutter

2 cutters, TiAlN-coated

Typ Z HA HB

VHM TiAlN N 2

No. 16742

Application: Centre cutting Shank HA

Radius milling cutter for universal use for copy mill- Full radius

ing in dip working and mould construction. No. 16742: Straight shank in accordance with DIN

6535 HA

Execution: No. 16743: Straight shank in accordance with DIN

Solid carbide ultra-fine grain 6535 HB No. 16743

TiAIN-coated

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16742 90 80 70 50 50 495 495 150 170 130 150 250 110 40 35 35

16743 90 80 70 50 50 495 495 150 170 130 150 250 110 40 35 35

Type N N

Surface TiAlN TiAlN

Tool holding device HA parallel shank HB parallel shank

Tolerance of cutting edge Ø e8 e8

Tolerance of shank Ø h6 h6

Z (PCS) fz steel 1000 16742... 16743...

(mm) Ident. No. Ident. No.

mm mm mm mm

3 8 62 3 2 0.02 030 ● - -

4 8 75 4 2 0.03 040 ● - -

5 9 75 5 2 0.038 050 ● - -

6 10 100 6 2 0.045 060 ● 060 ●

8 12 100 8 2 0.06 080 ● 080 ●

10 14 100 10 2 0.07 100 ● 100 ●

12 16 100 12 2 0.08 120 ● 120 ●

16 22 150 16 2 0.1 160 ● 160 ●

20 26 150 20 2 0.12 200 ● 200 ●

Prod. Gr. 154

Solid carbide radius cutter

2 cutters, TiAlN-coated

Typ Z HA

VHM TiAlN N 2

Application: Straight shank in accordance with DIN 6535 HA

Radius milling cutter for universal use for copy mill- TiAIN-coated

ing in dip working and mould construction. Centre cutting

Execution: Exact radius with a milling angle of 220°

Solid carbide ultra-fine grain

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16749 90 80 70 50 50 495 495 150 170 130 150 250 110 40 35 35

Type N

Surface TiAlN

Tool holding device HA parallel shank

Tolerance of cutting edge Ø f8

Tolerance of shank Ø h6

Z (PCS) fz steel 1000 16749...

(mm) Ident. No.

mm mm mm mm mm mm

1 0.7 5.7 60 0.9 6 2 0.014 110 ●

1.5 1.2 10 60 1.3 6 2 0.021 115 ●

2 1.5 11.5 60 1.7 6 2 0.028 120 ●

3 2.3 17.3 70 2.7 6 2 0.042 130 ●

4 3 23 70 3.7 6 2 0.056 140 ●

5 3.5 30 80 4.7 6 2 0.07 150 ●

6 4 50 90 5.7 6 2 0.084 160 ●

Source: Hahn+Kolb Werkzeuge GmbH

338 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.