Page 361 - Industrial Tools Catalog (1)

P. 361

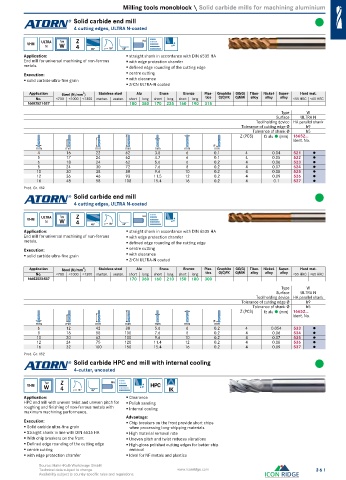

Milling tools monoblock \ Solid carbide mills for machining aluminium

Solid carbide end mill

4 cutting edges, ULTRA N-coated

ULTRA Typ Z HA

VHM W

N 4 γ = 18° 45°

Application: straight shank in accordance with DIN 6535 HA

End mill for universal machining of non-ferrous with edge protection chamfer

metals. defined edge rounding of the cutting edge

Execution: centre cutting

solid carbide ultra-fine grain with clearance

ZrCN ULTRA-N coated

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16652521-527 180 380 170 225 160 190 315

Type W

Surface ULTRA N

Tool holding device HA parallel shank

Tolerance of cutting edge Ø h9

Tolerance of shank Ø h5

Z (PCS) fz alu (mm) 16652...

Ident. No.

mm mm mm mm mm mm mm

4 16 22 62 3.8 6 0.1 4 0.04 521 ●

5 17 24 62 4.7 6 0.1 4 0.05 522 ●

6 18 24 62 5.6 6 0.2 4 0.06 523 ●

8 24 30 72 7.6 8 0.2 4 0.07 524 ●

10 30 38 80 9.6 10 0.2 4 0.08 525 ●

12 36 46 93 11.5 12 0.2 4 0.09 526 ●

16 48 58 108 15.4 16 0.2 4 0.1 527 ●

Prod. Gr. 152

Solid carbide end mill

4 cutting edges, ULTRA N-coated

ULTRA Typ Z HA

VHM W

N 4 γ = 18° 45°

Application: straight shank in accordance with DIN 6535 HA

End mill for universal machining of non-ferrous with edge protection chamfer

metals. defined edge rounding of the cutting edge

Execution: centre cutting

solid carbide ultra-fine grain with clearance

ZrCN ULTRA-N coated

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16652533-537 170 360 160 210 150 180 300

Type W

Surface ULTRA N

Tool holding device HA parallel shank

Tolerance of cutting edge Ø h9

Tolerance of shank Ø h5

Z (PCS) fz alu (mm) 16652...

Ident. No.

mm mm mm mm mm mm mm

6 12 42 80 5.6 6 0.2 4 0.054 533 ●

8 16 58 100 7.6 8 0.2 4 0.06 534 ●

10 20 62 100 9.6 10 0.2 4 0.07 535 ●

12 24 75 120 11.4 12 0.2 4 0.08 536 ●

16 32 100 150 15.4 16 0.2 4 0.09 537 ●

Prod. Gr. 152

Solid carbide HPC end mill with internal cooling

4-cutter, uncoated

Typ Z HA

VHM HPC

W 4 γ = 16° 45° IK

Application: Clearance

HPC end mill with uneven twist and uneven pitch for Polish sanding

roughing and finishing of non-ferrous metals with Internal cooling

maximum machining performance.

Advantage:

Execution: Chip breakers on the front provide short chips

Solid carbide ultra-fine grain when processing long-chipping materials

Straight shank in line with DIN 6535 HA High material removal rate

With chip breakers on the front Uneven pitch and twist reduces vibrations

Defined edge rounding of the cutting edge High-gloss polished cutting edges for better chip

centre cutting removal

with edge protection chamfer Ideal for NF metals and plastics

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 361

Availability subject to country specific rules and regulations.